STEEL MUST LAST

Climate requirements, globalization and geopolitical conflicts pose major challenges for companies that produce and process steel. This makes quality assurance all the more important to ensure that the precious raw material is used as efficiently as possible and rejects are avoided. SPC Werkstofflabor GmbH supports steel producers and processors as a service partner – and relies on a combination of light and scanning electron microscopy from ZEISS.

“The steel industry is in a difficult situation: Whether in the automotive, engineering, construction, or electronics industries – the demands on components made of steel are becoming ever higher. At the same time, supply is falling and prices for crude steel are rising,” reports Alexander Maier. As managing director of the accredited materials laboratory SPC, he could almost be pleased about this. Because, he continues, “We notice that companies have more need for quality assurance as a result in order to increase the efficiency of their processes. And that’s exactly our business as a service partner for materials testing and failure analysis.” At the same time, for him and his team, the joy is limited. Because firstly, the main cause of the particularly difficult situation right now, geopolitical conflicts, is distressing; secondly, it means that it is more difficult to plan orders. This makes the long-standing partnership with ZEISS all the more important for SPC, says Alexander Maier: “Optimally matched hardware and software solutions, cloud services for sharing results and powerful automation functions mean that we reliably deliver reproducible results, and do so as efficiently as possible – which is exactly what is needed in the current situation.”

“The steel industry is in a difficult situation: Whether in the automotive, engineering, construction, or electronics industries – the demands on components made of steel are becoming ever higher. At the same time, supply is falling and prices for crude steel are rising,” reports Alexander Maier. As managing director of the accredited materials laboratory SPC, he could almost be pleased about this. Because, he continues, “We notice that companies have more need for quality assurance as a result in order to increase the efficiency of their processes. And that’s exactly our business as a service partner for materials testing and failure analysis.” At the same time, for him and his team, the joy is limited. Because firstly, the main cause of the particularly difficult situation right now, geopolitical conflicts, is distressing; secondly, it means that it is more difficult to plan orders. This makes the long-standing partnership with ZEISS all the more important for SPC, says Alexander Maier: “Optimally matched hardware and software solutions, cloud services for sharing results and powerful automation functions mean that we reliably deliver reproducible results, and do so as efficiently as possible – which is exactly what is needed in the current situation.”

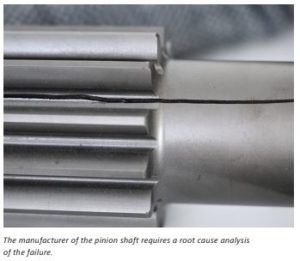

Quality of crude steel and recycled content down Thomas Schaupp is laboratory manager at SPC. He, too, knows the pain of the steel industry all too well: “A very high percentage of crude steel came from Russia until two years ago, and it was very high quality. Because of the economic sanctions, Germany now gets its steel from other markets that don’t always deliver comparable quality.” The industry is also increasingly mixing a certain amount of scrap into the crude steel – for economic reasons, but also to meet the growing demand for greater sustainability with more circularity. “But scrap quality is also declining,” says Thomas Schaupp. “And this overall situation – lower quality crude steel and poorer scrap – is causing steel processing companies to experience material quality issues they haven’t seen in many years.” This often has serious consequences for the resulting components, as in the case of a pinion shaft submitted for testing by one of SPC’s customers, a steel processor.

“We are noticing that companies (…) have a greater need for quality assurance in order to increase the efficiency of their processes (…).”

Thomas Schaupp explains: “The manufacturer of the pinion shaft complained to the steel trader after a complete batch of pinion shafts cracked lengthwise in the manufacturing process. The steel trader commissioned us to investigate the cause.”

Inspection process with combination of light and scanning electron microscopy “At first glance, the fracture looked to us as if it had been caused by damage to the surface of the raw part during hardening process,” reports Thomas Schaupp, “in other words, a crack from the outside in.” But the high-resolution analysis of a broken piece taken from a destroyed pinion shaft with the ZEISS Smartzoom 5 digital microscope suggests a different conclusion: “Even with the naked eye, we could see from the sample taken that the steel on the center axle is heavily darkened on the inside, which decreases towards the outside,” says Thomas Schaupp. “ And the microscopic analysis shows: around the central axis, a so-called ‘scaling’, i.e. oxidation of the steel, is visible. So the fracture originated from the inside.” To analyze the structure inside even more precisely, SPC staff created another sample, a metallographic section embedded in black epoxy resin, polished smooth and treated on the surface with an acid. “The etching process causes a chemical reaction of the material,” explains Thomas Schaupp. “This allows us to see under the microscope whether and where there is any contamination in the material.”

Inspection process with combination of light and scanning electron microscopy “At first glance, the fracture looked to us as if it had been caused by damage to the surface of the raw part during hardening process,” reports Thomas Schaupp, “in other words, a crack from the outside in.” But the high-resolution analysis of a broken piece taken from a destroyed pinion shaft with the ZEISS Smartzoom 5 digital microscope suggests a different conclusion: “Even with the naked eye, we could see from the sample taken that the steel on the center axle is heavily darkened on the inside, which decreases towards the outside,” says Thomas Schaupp. “ And the microscopic analysis shows: around the central axis, a so-called ‘scaling’, i.e. oxidation of the steel, is visible. So the fracture originated from the inside.” To analyze the structure inside even more precisely, SPC staff created another sample, a metallographic section embedded in black epoxy resin, polished smooth and treated on the surface with an acid. “The etching process causes a chemical reaction of the material,” explains Thomas Schaupp. “This allows us to see under the microscope whether and where there is any contamination in the material.”

For this purpose, the SPC staff examined the sample with ZEISS Axio Imager, a high-resolution wide-field microscope for automated materials research. Thomas Schaupp reports: The final step was to identify what materials the contamination consisted of. To do this, the staff examined a metallographic section from the pinion shaft using the ZEISS EVO scanning electron microscope, whose additional energy dispersive spectroscopy (EDX) capability allows them to perform a chemical material analysis in which an electron beam excites the atoms in the sample and the resulting X-rays are measured. The analysis shows: In the steel of the pinion shaft, there were non-metallic inclusions with high concentrations of manganese and sulfur near the central axle, as well as segregations of sulfur and phosphorus. Thomas Schaupp explains: “Normally, these impurities would still be tolerable, but a hole was drilled at precisely this point, which put particular strain on the material, and fracture occurred.” His assessment of the facts: “Yes, the steel supplied by our customer was contaminated, but this was within the norm. The company that made the pinion shaft from it should have required tighter tolerances for this application, in my opinion.”

ZEISS as a partner: 30 % faster to reliable results Thanks to the correlative workflow between light and scanning electron microscopy from ZEISS, the SPC materials laboratory was able to determine this result within a few days. says Thomas Schaupp. “Defects in materials such as steel lead to high costs for our customers. It must be possible to find and eliminate the causes quickly, otherwise deliveries are delayed, which can quickly become expensive.” The acquisition of equipment for the laboratory is the responsibility of Thomas Schaupp as laboratory manager, and for him there is no alternative for ZEISS. “Two things make ZEISS unique: First, the optimally matched hardware and software, something you don’t find with any other manufacturer. Everything works intuitively and simply, as well as quickly and efficiently thanks to the automation functions. With other solutions, we would have to spend 30 percent more time. This is important for SPC, especially in times of a shortage of skilled workers and high workloads”, he reports: The second major advantage of ZEISS over other providers is the cloud-based database ZEISS ZEN Data Storage, which allows the results of material analyses to be shared transparently and conveniently with customers.

ZEISS and SPC have enjoyed a close partnership for many years – and according to Thomas Schaupp, this will not change: “There are short distances to ZEISS in every respect. If we need service, it’s quick, we know each other, and ZEISS understands our needs. So why should we change anything?”