Unlocking the Power of Autobits IIoT Gateway: A Game-Changer for Industrial Monitoring

In today’s fast-paced industrial environment, having access to real-time data and the ability to analyze it quickly is essential. The Autobits IIoT Gateway simplifies the integration of data collection and reporting, making it easier than ever to optimize your operations.

Say Goodbye to Manual Data Collection

In the past, generating reports and accessing data meant spending hours manually collecting information from HMIs (Human-Machine Interfaces) and SCADA systems. These processes were not only time-consuming but also prone to errors.

With the Autobits IIoT Gateway, all of that has changed. Now, you can seamlessly connect your machines to the Autobits IIoT cloud platform, where data is automatically collected, analyzed, and stored. This means no more USB drives, no more manual transfers, and no more waiting for reports.

Simple Integration, Big Results

The Autobits IIoT Gateway is designed for easy integration. You don’t need to be a coding expert to get started. Just plug it into your existing systems, and it starts working immediately. The gateway is compatible with a wide range of industrial protocols, ensuring that it can connect to nearly any machine or device on your factory floor.

Accessing & Analyzing Data on HMI vs. IIoT Cloud

| Feature | HMI & Manual Data Collection | Autobits IIoT Cloud Platform |

| Data Accessibility | Local only, requires physical access | Accessible from anywhere via the cloud |

| Data Collection | Manual (via USB drives) | Automatic and real-time |

| Data Storage | Limited by local storage capacity | Unlimited cloud storage |

| Data Analysis | Manual compilation required | Automated analysis with visual dashboards |

| Notification System | None | Automated email alerts |

| Historical Data Access | Requires manual backup | Available anytime, stored for the lifetime of the equipment |

Effortless Report Generation

Generating reports on key performance indicators (KPIs) like efficiency, OEE, costing, and performance used to be a hassle. With traditional SCADA systems, it involved piecing together data from different sources, often requiring complex coding and configurations.

With the Autobits IIoT Gateway, generating these reports is a breeze. The data is continuously collected and processed in real-time, allowing you to generate detailed reports with just a few clicks. The platform is user-friendly and doesn’t require any coding knowledge, so anyone in your team can use it.

Generating Reports on SCADA vs. IIoT Cloud

| Feature | Traditional SCADA Systems | Autobits IIoT Cloud Platform |

| Report Generation | Manual, time-consuming | Automated and instant |

| Customization | Limited, requires coding | Flexible, code-free |

| Visualization | Basic, often limited to tables | Advanced, includes graphs and charts |

| Ease of Use | Requires technical expertise | User-friendly interface |

| Notification Capabilities | Limited | Automated notifications and alerts |

| Data Integration | Manual, complex | Seamless, real-time |

Visualize and Act on Your Data

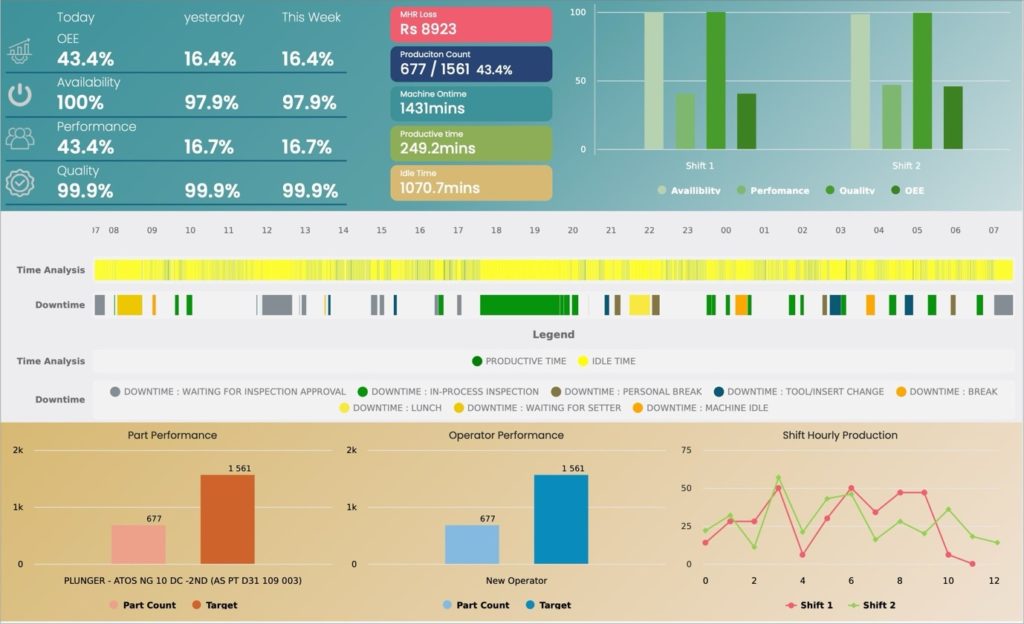

Having data is one thing; being able to visualize and act on it is another. The Autobits IIoT cloud platform offers powerful tools for graphical analysis. You can create custom dashboards that display the KPIs that matter most to your operations, all in real-time.

This code-free platform allows you to easily set up visualizations and receive automated email alerts when something needs your attention. This way, you’re always in the loop, even if you’re not on-site.

Case Study: How We Detected HVAC Anomalies with Autobits IIoT

Let’s take a real-world example. A manufacturing facility was facing issues with its HVAC system—temperatures were fluctuating, causing inefficiencies. Despite regular maintenance, the problem persisted.

By using the Autobits IIoT Gateway, the facility was able to collect and analyze temperature data automatically. The Autobits platform’s algorithms detected a subtle trend: a gradual increase in temperature during specific periods, which was linked to a decrease in system efficiency. The platform flagged this anomaly, allowing the team to schedule maintenance before the issue escalated. As a result, they avoided costly downtime and restored the HVAC system’s performance.

Lifetime Data Access and Instant Notifications

One of the standout features of the Autobits IIoT platform is lifetime data access. Unlike traditional methods where data had to be manually backed up and was often lost over time, the Autobits platform ensures that all your data is securely stored in the cloud. This means you can access historical data anytime you need it.

Moreover, the platform can send automated notifications via email, alerting you to any critical issues in real-time. This proactive approach to monitoring ensures that you can act quickly to prevent any potential problems.

Moving Beyond SCADA: The Future is Here

While SCADA systems have served industries well, they have their limitations. The Autobits IIoT Gateway is the next step forward, offering a more flexible, scalable, and user-friendly solution for industrial monitoring.

By embracing this technology, you can unlock new levels of efficiency, productivity, and innovation. Whether you’re managing a single machine or an entire factory, the Autobits IIoT Gateway makes it easier than ever to stay on top of your operations.