NORD DRIVESYSTEMS at interpack 2023 High efficiency drive solutions for the packaging industry

At interpack in Dusseldorf, the drive specialist NORD DRIVESYSTEMS will present its wide product portfolio and great expertise in the packaging industry from 4 to 10 May 2023 – from decentralised frequency inverters to energy-efficient drives to high-performance surface treatments for wash-down or spray areas.

Whether primary, secondary or end-of-line packaging: For all stages in the packaging process, NORD DRIVESYSTEMS implements economical, sustainable and tailor-made drive solutions that optimally meet the relevant application-specific requirements and, at the same time, can contribute to a considerable reduction of the Total Cost of Ownership (TCO). Visit the NORD stand C26 in Hall 6 at the interpack trade fair to find out what that means for customised applications. The North German drive specialist will present its modular products and its great expertise in the field of packaging automation. The exhibition highlights include the decentralised frequency inverter NORDAC ON/ON+, the IE5+ synchronous motor, the patented DuoDrive geared motor and the nsd tupH surface treatment. NORDAC ON/ON+: Decentralised frequency inverter with integrated Ethernet interface The decentralised frequency inverter NORDAC ON/ON+ is characterised by an integrated Ethernet interface (Profinet, EtherNet/IP and EtherCAT can be set via parameters), full plug-in capability and a very compact design. The smart inverters are ideally suited for integration into packaging machinery, saving space as well the extensive motor cable wiring required for centralised frequency inverters. There are two versions

available: NORDAC ON has been designed for use with asynchronous motors whereas NORDAC ON+ is intended for the combination with high-efficiency IE5+ synchronous motors.

NORDAC ON/ON+: Decentralised frequency inverter with integrated Ethernet interface

The decentralised frequency inverter NORDAC ON/ON+ is characterised by an integrated Ethernet interface (Profinet, EtherNet/IP and EtherCAT can be set via parameters), full plug-in capability and a very compact design. The smart inverters are ideally suited for integration into packaging machinery, saving space as well the extensive motor cable wiring required for centralised frequency inverters. There are two versions available: NORDAC ON has been designed for use with asynchronous motors whereas NORDAC ON+ is intended for the combination with high-efficiency IE5+ synchronous motors.

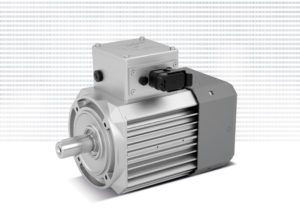

IE5+ motor generation: Efficiency at a new level

IE5+ motor generation: Efficiency at a new level

With the IE5+ synchronous motor, NORD is setting new energy efficiency standards. Thanks to permanent magnet synchronous motor technology (PMSM), it achieves an efficiency of up to 95 percent – and this is relatively constant over a wide speed and torque range. The IE5+ motor thus provides an optimal energy consumption performance in partial load and partial speed ranges and even tops the highest defined energy efficiency class IE5.

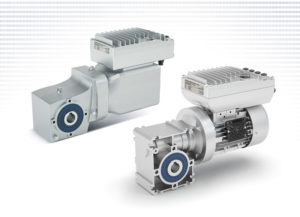

DuoDrive: Seamless integration of gear unit and motor

The patented DuoDrive is a revolutionary integrated gear unit/motor concept that covers power ranges of up to 3 kW. It combines the high-efficiency IE5+ motor and a single-stage helical gear unit in one housing. The constant motor torque over a wide speed range allows for consistent variant reduction and reduction of operating costs. Together with the simple plug-and-play commissioning, this results in a significant reduction in the Total Cost of Ownership (TCO) in comparison with existing drive systems. The unventilated wash-down design with smooth surfaces meets the most stringent hygiene requirements and ensures optimum outstanding corrosion protection for gear units, smooth surface motors, frequency inverters and motor

starters in wash-down optimised cast aluminium housings Image: NORD DRIVESYSTEMS nsd tupH surface treatment: An alternative to stainless steel The nsd tupH surface treatment is available for NORDAC ON/ON+ as well as the IE5+ synchronous motor and the DuoDrive geared motor. Thanks to a special method, the surface is made corrosion-resistant and harder and makes aluminium behave like stainless steel with regard to corrosion protection. This is not a coating, but a surface treatment that creates a protective layer which is permanently bonded to the substrate

material. So nothing can detach or flake off. The drives are easy to clean and largely resistant to acids and alkalis.

About NORD DRIVESYSTEMS

With approx. 4,700 employees today, NORD DRIVESYSTEMS has developed, produced and sold drive technology since 1965, and is one of the leading global full-service providers in the industry. In addition to standard drives, NORD delivers application-specific concepts and solutions for special requirements such as energy-saving drives or explosion-protected systems. In the 2021 financial year, annual sales amounted to 870 million Euros. NORD has 48 subsidiaries in 36 countries and further sales partners in more than 50 countries. They provide technical support, local stocks, assembly centres and customer service. NORD develops and produces a wide range of drive solutions for more than 100 industries, gear units for torques from 10 Nm up to over 282 kNm, supplies electric motors in the power range of 0.12 kW to 1,000 kW, and supplies the required power electronics with frequency inverters of up to 160 kW. Inverter solutions are available for conventional control cabinet installations as well as for decentralised, fully integrated drive units.

www.nord.com

NORD DRIVESYSTEMS Private Limited

282/2 & 283/2,Plot No.15,Village Mann, Taluka Mulshi, Adj.Hinjewadi MIDC Phase II, Pune 411057 Maharashtra INDIA

Snehal Dhamankar

Phone: +91 20 39801- 217

Fax: +91 20 39801- 416

Snehal.Dhamankar@nord.com

Getriebebau NORD GmbH & Co. KG

Getriebebau-Nord-Straße 1

22941 Bargteheide/Hamburg

Germany

Jörg Niermann

Phone: +49 45 32 / 2 89 -0

Fax: +49 45 32 / 2 89 -22 53

Joerg.Niermann@nord.com