ANCA Motion’s technology helps to drive sustainability and efficiency in the Industrial Automation industry

Automation technology is changing rapidly, and with it comes an increasing need for solutions that are high speed, precise, easy to use and environmentally friendly. In India, the automation industry is witnessing a shift towards high efficiency, better reliability, and supportive solutions that are compliant with local standards and assist organizations to achieve carbon neutrality.

Automation technology is changing rapidly, and with it comes an increasing need for solutions that are high speed, precise, easy to use and environmentally friendly. In India, the automation industry is witnessing a shift towards high efficiency, better reliability, and supportive solutions that are compliant with local standards and assist organizations to achieve carbon neutrality.

ANCA Motion promises to satisfy all these features with a range of solutions suited for the Industrial Automation industry.

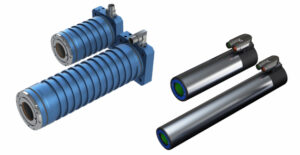

LinX®: Latest technology energy efficient motors

LinX® motors were originally developed to provide a competitive edge for ANCA’s world-leading 5-axis grinding machines in their bid to overcome the traditional shortcomings of ballscrew and flatbed linear motors.

This new technology of linear motors is gaining huge traction in highly dynamic applications within industries as diverse as packaging, printing, food processing, pharmaceutical and material handling.

LinX® tubular motors are direct drive motors and due to its cylindrical construction and fully potted body, LinX® motors can achieve a higher IP rating and produces zero down force on the bearings there by reducing wear. This aids in achieving a highly dynamic performance with reduced maintenance costs.

Recently, ANCA Motion partnered with a leading supplier of food packaging machinery to successfully develop and deliver a bespoke LinX® motor for their niche application which required chemical wash down, higher acceleration and a unique motion profile. The solution also helped the customer to achieve quicker installations, increased the safety of their operators significantly and capture new markets previously unserved by them.

These drives can be used with ANCA Motion’s Alpha and Gamma series servo motors. These motors provide a speed of up to 6000rpm at different power and torque requirements.

As seen in the automation industry, a simple machine control interface is needed to operate the system reliably from far end as good as 10m from the machine. ANCA Motion supports this with its AMI 5000 Remote Pendant.

As seen in the automation industry, a simple machine control interface is needed to operate the system reliably from far end as good as 10m from the machine. ANCA Motion supports this with its AMI 5000 Remote Pendant.

Its superior compatibility with any Ether CAT Host system via Plug & Play and full customization, inclusive of buttons and artwork, to meet any organization’s branding requirements made it a success story for companies such as Tru Tech, Space-X, and Techni. With its easy-to-use grip and mounting mechanism, it offers customers the unique benefit of simple and reduced time to integrate.

To monitor the process and to intiate sequences, machine designers rely on HMI Panels with user interface which are often found in oily environments around machines. Frequent handling by operators with greasy hands degrade the screen quickly, resulting in high maintenance costs or halting operations. The HMI Touc hpad offered by ANCA Motion has an oil resistant screen designed to with stand tough machine environments. The Touch screen offers a 19 inch active display area which is fully customizable thereby simplifying the direct interaction with machine. ANCA Motion offers the Touch pad in two variants, Pivot and Mounting Arm, with both directly mounted to interface with the ANCA Motion control system and support fast and flexible access for real time control.

Customizable touch pad: Suited for oily environments

Customizing the interface often requires engineers with expertise in programming. However, ANCA Motion’s Touch Pad uses Commander software which provides the framework to build a custom interface with rich visuals and custom functionality, without the need for programming skills. The “Design and create your own GUI” approach provides a unified and consistent user experience especially useful for those without domain knowledge. It is flexible and customizable to suit varying business requirements.

ANCA Motion: Your business partner in Customizable solutions

The time is now for OEMs in industrial automation to provide customized solutions with confidence to valuable customers. ANCA Motion provides its best support as a partner to OEMs and machine manufacturers, designing and providing customized, high precision motion control solutions all over the world.

ANCA Motion is a division of the ANCA Group, a market leading manufacturer of motion control systems, CNC grinding machines and sheet metal solutions. ANCA Motion designs and manufactures flexible control systems, specialising in high precision solution for CNC and automation.

With headquarters in Australia and representation in the rest of world directly and indirectly, ANCA Motion has been involved in motion control for more than 45 years. Its CNC and motion control technology has evolved over this time by proving its performance in demanding applications such as five-axis grinding, high speed laser cutting and factory automation. ANCA Motion offers a range of solutions from turnkey automation control packages to single components such as servo drives, motors, IO modules, HMI and software. One of the company’s strengths lies in its partnership with customers to create a bespoke solution, satisfying their unique needs.

Bessemer Road, Baywater North VIC 3153

Australia Tell: +61397518900

India Tell: +91 6366449980

www.ancamotion.com