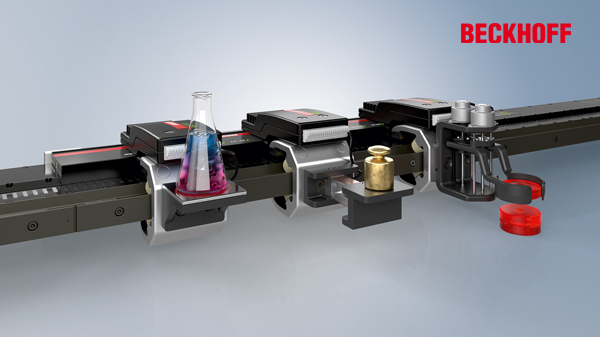

XTS transport system with innovative No Cable Technology (NCT)

Contactless power and data transmission for the movers

Beckhoff achieves a new quantum leap in terms of machine flexibility with the innovative No Cable Technology (NCT) for the XTS intelligent transport system. This is made possible by contactless power supply and synchronous real-time data communication, enabling individual XTS movers to be expanded into mobile handling and processing stations.

The modular XTS system has been expanded with NCT to include a special motor module as well as electronics that can be mounted on the movers. The hardware required for the transmission technology is fully integrated into the motor module, so that the existing functionalities and compact set-up are retained. No additional connections or supply lines are needed. The control of the hardware on the mover is fully implemented in TwinCAT. All known TwinCAT functionalities are available for simple project implementation.

For the first time, NCT makes it possible to process and check the quality of products on the mover while the process is running. Sufficient power and fast communication with the TwinCAT control system enable easy connection of sensors and actuators. The data communication is real-time capable and can synchronize system-wide events with µs accuracy in connection with EtherCAT. This opens up new solution options for the user, especially in the areas of product handling, machining and measuring in parallel with product transport, as well as adapting production machines for rapidly changing production lots:

- Various motion sequences can be implemented on the mover itself, for example, to align a product.

- The mover becomes a mobile handling system with electromotive grippers, lifting magnets or vacuum suction cups that can pick up, transfer and deposit products.

- Heating or cooling of products during transport is just as possible as performing inline measurement.

- The integrated data communication enables, for example, unique mover, toolbox and product identification as well as state and process monitoring on individual movers

For more details please contact:

Beckhoff Automation Pvt Ltd.

http://www.beckhoff.com/

Email: info@beckhoff.co.in