Innovative drive concepts from NORD : More efficiency in warehouse automation

E-Commerce is booming and so is warehouse automation. Flexible warehouse systems are also in demand in large grocery chain warehouses, and require environmentally friendly, sustainable and intelligent drive concepts. Drive specialist NORD DRIVESYSTEMS is highly familiar with the industry’s requirements and offers a variety of dynamic drive solutions which are suited for various applications and requirements in warehouse logistics.

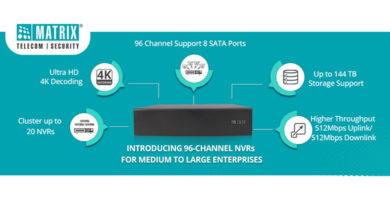

NORD DRIVESYSTEMS provides a comprehensive modular system for individual and scalable drive solutions that ideally suit the warehouse area Image: NORD DRIVESYSTEMS

NORD offers customised drive solutions for warehouse logistics for an optimum compromise between investment, operating and maintenance costs. With motor efficiency class IE4 and system efficiency class IES2, the drive units achieve excellent efficiencies – especially in the partial load and speed range. The latest generation IE5 permanent magnet synchronous motors achieve an even higher energy efficiency and significantly reduces the energy consumption. The constant torque over a wide speed range allows for a targeted version reduction. This minimises administrative expenses, and enables leaner manufacturing, logistics, storage and service processes.

The decentralised NORDAC ON frequency inverter

The decentralised NORDAC ON frequency inverter has been developed for horizontal conveyor technology requirements in warehousing, and the NORDAC ON+ variant for interaction with the new IE5+ synchronous motor. It is characterised by an integrated Ethernet interface, its ease of maintenance through complete pluggability and an extremely compact design – providing an economical and intelligent plug-and-play solution for IIoT environments. The compact, smart frequency inverter for decentralised use can be mounted directly on the geared motor. It covers lower power ranges of up to 2.2 kW and has an energy-saving function in the partial load range. The integrated Ethernet interface reduces the effort for integration into modern automation systems: Whether for ProfiNet, EtherNet/IP or EtherCAT, the required protocol can be easily set via parameters.

More efficiency in conveyor technology

The NORDAC FLEX SK 205E series is also ideally suited for applications in warehouse logistics. The compact, decentralised and energy-efficient frequency inverter offers a wide power range of up to 22 kW and enables energy savings over the entire load range. The inverter can be used to control standard asynchronous motors, high-efficiency synchronous motors and brake motors. It can be installed close to the drive in the field or motor-mounted. Power and data cable connections are available as plug-in versions. The decentralised system enables short motor and encoder cables as well as short supply cables to sensors.

Encoder feedback can be included, for example, for position-controlled transport systems. The large overload capacity of the NORDAC FLEX SK 205E makes dynamic movements with short start and stop times or cyclic operation possible. The integrated POSICON control enables high precision in synchronous and positioning applications.

Modular system for optimal drive solutions

Overall, NORD convinces with a wide range of products in the field of warehousing, including both established basics and high-efficiency products. Users benefit from tailored and reliable drive solutions which ensure an optimum system availability. The NORD modular drive system thus enables an optimum compromise between investment, operating and maintenance costs.

words:Werehouse,automation,drive concepts

Deeplinks:

https://info.nord.com/en/ie5

https://www.nord.com/en/products/drive-electronics/decentral-drive-

solutions/sk-300p-nordac-on-on-frequency-inverter.jsp

https://www.nord.com/de/loesungen/branchen/intralogistik-flughafentechnik/intralogistik.jsp

Social Media:

LinkedIn profile:

https://www.linkedin.com/company/getriebebau-nord-gmbh-&-co-kg/

LinkedIn links: @Getriebebau NORD GmbH & Co. KG

Twitter: https://twitter.com/NORD_Drive

Twitter links: @NORD_Drive

YouTube: https://www.youtube.com/user/NORDDRIVESYSTEMS

About NORD DRIVESYSTEMS

With approx. 4,700 employees today, NORD DRIVESYSTEMS has developed, produced and sold drive technology since 1965, and is one of the leading global full-service providers in the industry. In addition to standard drives, NORD delivers application-specific concepts and solutions for special requirements such as energy-saving drives or explosion-protected systems. In the 2021 financial year, annual sales amounted to 870 million Euros. NORD has 48 subsidiaries in 36 countries and further sales partners in more than 50 countries. They provide technical support, local stocks, assembly centres and customer service. NORD develops and produces a wide range of drive solutions for more than 100 industries, gear units for torques from 10 Nm up to over 282 kNm, supplies electric motors in the power range of 0.12 kW to 1,000 kW, and supplies the required power electronics with frequency inverters of up to 160 kW. Inverter solutions are available for conventional control cabinet installations as well as for decentralised, fully integrated drive units.

www.nord.com

Getriebebau NORD GmbH & Co. KG

Getriebebau-Nord-Straße 122941 Bargteheide/Hamburg

Germany Jörg NIERMANN Phone: +49 45 32 / 2 89 -0,

Fax: +49 45 32 / 2 89 -22 53 Joerg.Niermann@nord.com