Exclusive: Interview with Mr. Rahul Diwan, India Manager ANCA Motion

A&I: It’s great to invite you for this interview, Mr. Diwan. Firstly, can you please brief us about your journey with “ANCA Motion”?

Rahul: Thank you editor. I have always been passionate about Manufacturing in India – it teaches great skills and provides stable jobs. It has been my dream to have the world come to India to have their engineering products Made in India.

![]()

Mr. Rahul Diwan, India Manager, ANCA Motion

Throughout my career, of almost thirty years, I have worked with different CNC systems, both technically and at a business development level. Not only has this provided me with the fortunate opportunity to experience most CNCs and servos, it has given me the privilege of witnessing how Manufacturing in India has improved, grown and developed. I have thoroughly enjoyed working alongside customers to solve their motion control problems and challenges. I have been lucky enough to experience this in different regions in India, in a variety of verticals of the machine tool industry as well as industrial automation. Personally, I have always found much satisfaction in working closely with every customer – from end-users to system integrators and OEMs – each customer situation is different and provides unique challenges.

During my journey, whenever I came across machines from ANCA Machine Tools, I was highly impressed by the whole system – features such as multi-axis control; a classic software; operator- friendly GUI; 3D simulation and precise nano control, to name a few. All this makes a machine manufactured by ANCA Machine Tools a highly desirable and well-sort after, and arguably making ANCA Machine Tools number one in tool-cutter grinding machines. The powerful CNC system behind these machines is ANCA Motion!

Hence, I was so excited to be given the opportunity to work with ANCA Motion as the Business Development Manager – India, and to make available to the manufacturers in India such great, innovative technology and take ANCA Motion’s CNC system and applications to the India market place. Despite the challenges I have faced since joining over the past 2 years, every day I have been excited to explore all the opportunities to work together with customers in solving their motion control challenges and making the project a success. To date, we have been connecting with select OEMs in the market for different niche applications like grinding, laser cutting, automation, packaging, and food processing using the whole product lineup.

The next phase is just as exciting. We are in the process of growing a robust technical support network in India. With plans ahead to set up a service and repairs centre in the very near future. I have an insight as to what makes ANCA Motion stand ahead in the competition, and with the customers that we have worked alongside to date, I have witnessed how committed and dedicated they are in making their customers be successful. I am humbled and honoured, to be entrusted help our customers here in India in their chosen market, domestically and internationally.

A&I: Can you take us through the history of ANCA Motion’s CNC system?

Rahul: The years of focussing on the precision of movement; efficiency; superior processing; speed; quality; easy-to-use; etc ANCA Motion’s high-performance, flexible and easy-to-use general CNC system is based on our proven track record of experience in various high-precision 5-axis machine tool applications. In the past half-century, we have created a history of numerous “number ones” in the CNC industry when solving customers’ practical problems. One out of these examples is the in-cycle MPG Feed feature. This feature allows operators to move synchronized joints/axis freely and easily along programmed contouring paths and dramatically simplifies the machine commission and job setup. In-cycle MPG Feed is still considered as a premium feature in today’s high-end CNC control systems, while ANCA introduced it to the market almost 30 years ago! Meanwhile, ANCA Motion is an early adopter of the EtherCAT fieldbus technology. Leveraging EtherCAT’s excellent real time performance, our system can achieve superior synchronization between different axis, which is crucial to 5-axis machine tools applications.

ANCA Motion Founders Pat McCluskey and Pat Boland back in 1970s

ANCA Motion’s general CNC control system is a benchmark for world-class control performance. Our CNC can process 300,000 blocks per minute which enables the most demanding machining profiles, like in Die & Mould . ANCA Motion is also one of the few CNC control suppliers who can offer nano- meter resolution in their control solution, resulting in the finest surface finish. Utilizing our in-depth motion control expertise, ANCA Motion developed various innovative features to keep our OEM customers on top of the competitions. To improve machining efficiency, many OEMs adopted linear motors in their machines. However, traditional flatbed linear motors also brought their own problems to the machines, for example, high down forces, low stiffness, etc. To solve these problems, ANCA Motion’s answers are our innovative LinX® tubular linear motors and a unique anti disturbance algorithm. The machines equipped with ANCA Motion’s linear motor solution can achieve improved surface finish at a faster cycle time, providing our OEM customers a competitive edge in their market.

Distinguished from most of traditional CNC control suppliers, we offer a fully opened system. Our NC core runs on top of the standard Windows operating system with a real-time kernel deployed. This provides familiar using experiences for both machine developers and operators. ANCA Motion’s general CNC system supports a wide range of standard interfaces, including EtherCAT, Modbus TCP, and OPC-UA, allowing seamless automation auxiliary equipment integration and easy IoT solution implementation.

Flexibility and easy-to-use are two key attributes of ANCA Motion’s general CNC system. Our Commander software gives OEMs the power to build custom interfaces with rich visuals, filled with custom intelligence and functionality, with no programming skills required. Complicated UIs can be created by simple drag-and-drop operations. Handy configuration tools, such as Motionbench, are provided to assist customers in machine commissioning in the factory or troubleshooting in the field.

The history of growing up embedded in a business, has ensured results. A key factor to ANCA Motion’s success is working alongside our customers in understanding their applications and developing state-of-the-art technologies in solving their challenges. In laser cutting space, the on-drive time stamped I/Os enables the best-in-class fly cutting performance. To reach the incredible 1,300 hole per minute small cycle laser cutting, we optimized our Jerk limiting control algorithm to the next level. The OptiGrind feature we developed for cylindrical grinding applications can reduce the cycle time of non- round work piece up to 50%, a breakthrough improvement to the industry.

ANCA Motion provides all the hardware products in a CNC control system including AMC6 fan-less CNC controller, AMD5x G2 multi-axis drive system, AMD2000 servo drives, EtherCAT-based HMI devices, a full Touch screen panel, rotary motors, LinX® linear motors and I/Os.

A&I: Take us through the Global Network & Infrastructure of ANCA Motion, in particular India?

Rahul: Headquartered in Melbourne, Australia, this is also where the R&D Central and the main Engineering are housed. Prior to joining ANCA Motion, I was already impressed. When I joined I was further impressed observing how the engineering team work together to deliver on outcomes which covers all aspects of CNC & Motion Control product development including core kinematics, application packages, servo control technologies, motors, and HMI devices. Innovation is not only a word for ANCA Motion, it is in our DNA. Upon joining, it was very easy to conclude that the critical success factor for ANCA Motion is the dedicated R&D department who looks after all state-of-the-art technologies as well as industrial trends. This ensures that our solution is ahead for today, and for tomorrow.

ANCA Motion Global Network

Complimenting the R&D Central and Engineering, are the Teams of Engineers that are located in the networks around the world. Their in-field experiences, and insights gained along-side customers, ensures that customer problems and practical application is forefront and central to all internal activities. Approaching the variety of Motion Control Projects from the many different perspectives is what drives leading edge solutions within ANCA Motion.

Our factory located in Taiwan enables us to leverage the best supply chain & logistics eco-system in the world. This compliments the Engineering resources well, delivering the state-of-the-art components for the Engineering solutions and outcomes.

So, “What does this mean for customers here in India?”

In the network, there are Stock; Spares; Warehouses; Engineers; Field Applications; approved Distributors and Agents that can be leveraged by You to develop the right Aftersales Service and Support to meet Your strategy and market needs. Like ANCA Motion CNCs and Applications, we will work with You so you can tailor the appropriate solution to meet Your strategy.

Key to delivering on solutions to customers is the ability to work alongside our customers technically. What this means for my team here in India, at this stage of our journey, is to have a strong technical support structure. Here in India, we have Field Application Engineers and Service engineers to support all regions. This team is well supported and backed up by the team at head office and as well as the broader team across the global network. This makes every challenge addressable, and a solution achievable, utilizing the capability of the network, and delivered by a local support alongside of you.

We can help you build and deploy intelligent manufacturing solutions faster and more efficiently by tapping into our extensive global industrial know-how.

A&I: Please brief us about the quality Policy for the business.

Rahul: From the moment I began working for ANCA Motion, Quality is first and foremost – and it explained what I had encountered in my earlier years when I came across ANCA Machine Tool products. Each and everyone in the company, globally, has a quality focus – it would be apt to represent that quality is a culture. We build the quality within every product, service, and offering on time, every time, with zero defects. All processes start and end with the controls in place for continuous improvement. This approach makes us continuously pushing to produce world-class products with an edge over the competitors.

When I travelled to the Melbourne headquarters, the process was observed, where all products are designed and built to operate fault free for the life of our customer’s equipment. We treat quality issues with a sense of urgency and ensure we have processes in place that promote permanent corrective actions. We commit to supporting our solutions throughout their operational life with spare parts and responsive service. To achieve this, we use well defined, documented, and repeatable processes for the entire product lifecycle. We monitor, measure, and refine these processes based on Lean principles. We understand that developing a culture of continuous improvement throughout the business in everything we do is fundamental in driving improved value creation for our customers.

The quality and reliability of solutions provided by ANCA Motion are the concern of every person in the organization.

A&I: How do you see the market opportunities in Industrial Automation and Machine Tool Industry in India? How do you plan to Position these Products?

Rahul: ANCA Motion Specialises in Tailoring Motion Control solutions i.e., customized support to our partners who want to distinguish from competition in some respect. ANCA Motion’s renowned CNC technology has been extensively developed for almost half a century. ANCA Motion’s CNC controls are utilized in thousands of industry leading machines around the globe.

In India, there is great opportunity for customers – OEMs in particular, and also System Integrators – to take advantage of these world-class engineered solutions. Not only to make great machines for the local India market place, but also to develop a great reputation on the world stage by utilizing and incorporating ANCA Motion products. It really excites me to be able to bring such world-class CNC products, systems, and applications to make it available for the India market as a resource.

Initially, the focus will be targeted to areas:

1. CyGrind – ANCA Motion’s cylindrical grinding solution is a complete CNC system package combining premium CNC performance with user-friendly cylindrical grinding software. CyGrind takes the complexity out of cylindrical grinding with innovative software navigation combined with 3D graphical feedback, touch-friendly interface and grinding simulation. CyGrind makes the complex, simple.

CyGrind – Cylindrical Grinding Solution

2. Pinch Peel Grinding – This is a niche grinding application where Rough & Finish operations are done in a single pass with a machine having two grinding wheels. This provides an exceptional performance and optimal concentricity. Although this concept may be new to some customers, it’s gaining popularity in many parts globally particularly in blank preparation. It is also expected to have its own place in the India market.

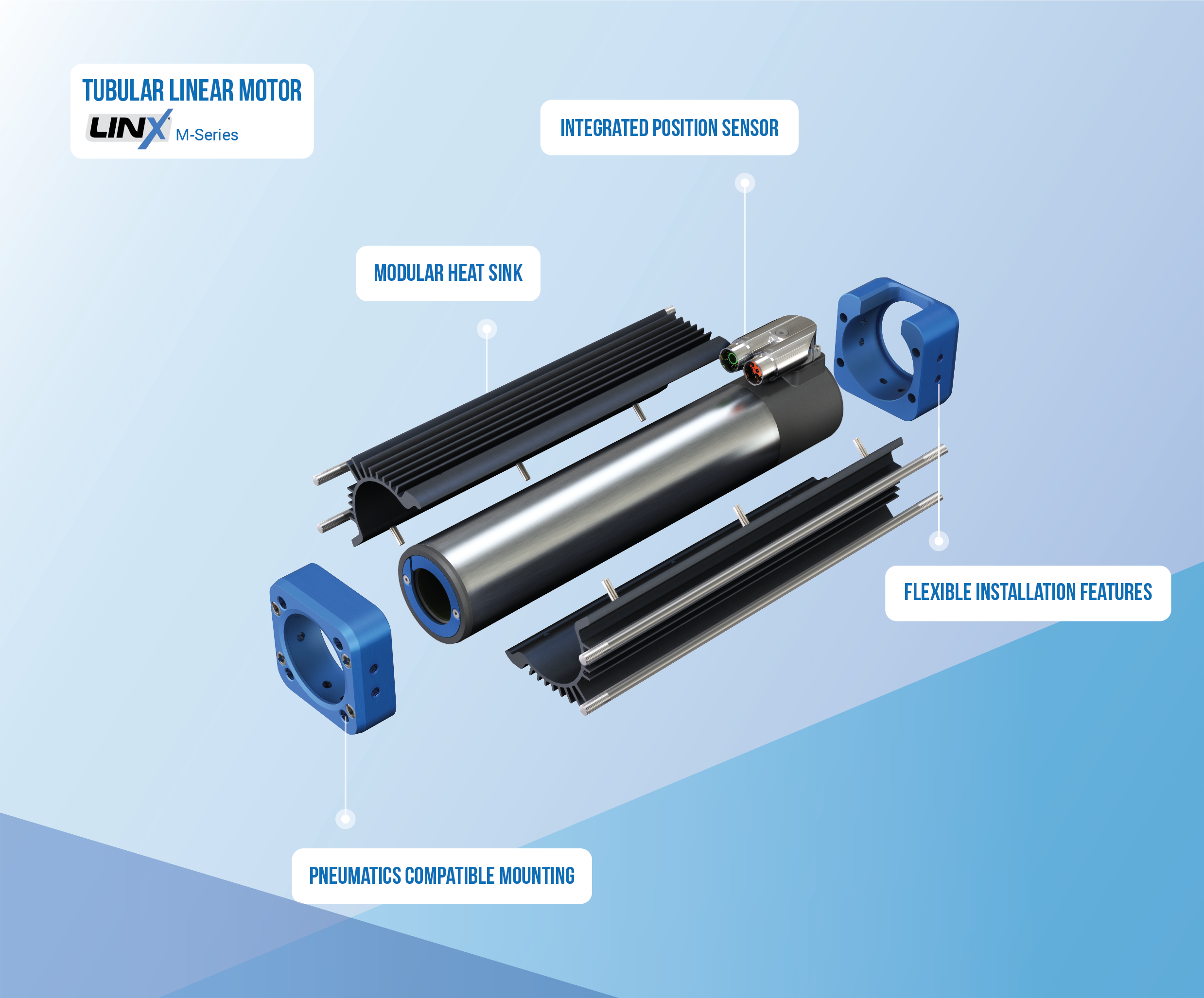

3. LinX® – Tubular linear motors – Zero net attractive forces – improve efficiency with no down force, extending machine life. Excellent environmentally responsible replacement Pneumatic replacement whilst also improving performance; as well as more responsive than Ball Screws; and a safer option that Flat Bed Linear Motors. This innovative product is suitable for a diverse end uses: ranging from Industrial Baking Houses; Plastic Bottle Blow Moulding; Hexapods/Rotopods; CNC Machine Retrofits; Vibration tables/units; variety of robot end-of-arm applications, it is only imagination that would limit us

a. LinX® S-Series – Designed for machine tools – Up to 630N continuous(4,270N peak).

b. LinX® M-Series – Highly dynamic for automation – Up to 287N continuous (1,200N peak).

LinX® M-Series Tubular Linear Motor

4. Laser tube cutting solution, TubeCut Master – This is ANCA Motion’s complete solution for all types of tube cutting like round or square with a very precise and faster control over the entire operation. It works with the direct operation on drawing that reduces the complexity in tube cut programming. Optimized Z-axis control across corner improves the speed without any compromise on the shape. This works on fast response of Height following control & special optimization for the tube corner to reach good performance across the corner and high efficiency. The OEM can make its own style GUI through very simple drag-and-drop operations. The communication between the machine’s CNC control and automation equipment can be via either I/Os or the Modbus TCP fieldbus. It provides automation support for loading/ unloading devices. The automation device is always checked through Modbus connection. Fully customized IoT applications are possible through TubeCut Master with standardized network interfaces – OPC UA.

5. Laser 2D cutting solution, Cut Assist – ANCA Motion’s Laser 2D Cutting control builds on our Profile Cutting control with additional capabilities specifically for Laser cutting. The control system provides full support for gantry machines, beam length control, height following, focal axis, and material handling. The open and flexible CNC includes support for advanced corner modes, custom kinematics, sheet qualification, and special move types designed to reduce cycle time and improve cut quality. By combining ANCA Motion CNC technology with the OEM’s engineered Laser Cutting solution the end machine is optimized for the application.

A&I: What is your vision & growth plans for “ANCA Motion” In India?

Rahul: The vision I have is not so much one for ANCA Motion, but more one for India – I would love for India to be known on the world-stage and have the reputation that we make world-class machines! ANCA Motion has the products, solutions, and above all the resources, that can assist the OEMs here in India in producing world-class machines.

At ANCA Motion, we design and manufacture flexible control systems, specializing in high precision CNC machines. The best results I have observed in my time at ANCA Motion are when we tailor our hardware and software to an OEM’s exacting requirements, providing solutions that give customers a competitive edge. If there is an application that requires precision, speed and complex motion control and you would like to take it to the world stage and put India on the map, this would be great honour to help you achieve this.

Fore more details Please contact

ANCA Motion

1 Bessemer Road, Bayswater North,

VIC, 3153 Australia

T: +61 3 9751 8900

India T: +91 636 644 9980

www.ancamotion.com

sales@ancamotion.com