Revolutionizing Industrial Automation with the Smart Supervisor Gateway

In the heart of industrial evolution, where efficiency, security, and real-time data processing converge, the Smart Supervisor Gateway stands out as a beacon of innovation. As industries face mounting pressures to streamline operations and enhance productivity, this cutting-edge IIoT (Industrial Internet of Things) solution offers a transformative approach to overcoming traditional challenges. Let’s delve into how the Smart Supervisor Gateway redefines industrial automation, its unique innovations, target audience, and practical applications.

Addressing the Present Challenges

Addressing the Present Challenges

Industrial operations are riddled with complexities, from managing extensive machinery networks to ensuring data security and achieving real-time responsiveness. Traditional monitoring systems often struggle with:

- Latency and Bandwidth Constraints:

- Reliance on cloud-based processing introduces delays, impairing real-time decision-making and operational agility. We also have to consider the downtimes in the network that attribute to loss of data.

- Data Security Risks:

- Transmitting sensitive industrial data over the internet exposes it to potential cyber threats and breaches.

- Interoperability Issues:

- Integrating devices from various manufacturers presents compatibility challenges, leading to inefficiencies and increased costs.

- Scalability Limitations:

- As operations expand, traditional systems struggle to scale efficiently, causing performance bottlenecks.

The Smart Supervisor Gateway Solution

Designed to tackle these challenges head-on, the Smart Supervisor Gateway combines advanced edge computing, robust security features, and seamless interoperability, offering an all-encompassing solution for modern industrial needs.

Innovations That Set It Apart

Innovations That Set It Apart

- Edge Computing Excellence:

- By processing data locally, the Smart Supervisor Gateway minimizes latency and reduces bandwidth usage, enabling real-time data analysis and immediate decision-making critical for dynamic industrial environments.

- Unmatched Security Measures:

- Incorporating multi-factor authentication, end-to-end encryption, and secure boot processes, the gateway ensures data integrity and protection against cyber threats, adhering to stringent industry standards.

- Seamless Interoperability:

- Supporting a broad range of industrial protocols including MQTT, Modbus, and OPC UA, the gateway integrates effortlessly with existing PLCs, SCADA systems, and other industrial devices, creating a unified communication platform. Support for Major PLC Protocols

- Scalability for the Future:

- Engineered to grow with your operations, the Smart Supervisor Gateway accommodates increasing numbers of connected devices and higher data volumes without performance degradation, ensuring long-term viability.

- Custom Scripts and Automation:

- The gateway’s support for custom scripts, such as Python, enables advanced data processing and automation tailored to specific operational needs, driving efficiency and productivity.

Benefits of Connecting the Gateway to Existing PLC Systems

Integrating the Smart Supervisor Gateway with existing PLC systems amplifies operational capabilities:

- Enhanced Data Collection and Analysis:

- Comprehensive data collection from connected devices allows for real-time analysis, optimizing operations and providing actionable insights.

- Operational Efficiency Boost:

- Seamless integration with PLC systems ensures efficient process monitoring and control, automatically adjusting parameters based on real-time data.

- Predictive Maintenance:

- By analyzing data trends, the gateway predicts equipment failures, enabling timely maintenance and reducing downtime, extending equipment lifespan.

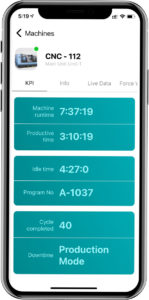

- Real-Time Monitoring and Control:

- Operators gain the ability to monitor and control industrial processes in real-time from any location, addressing issues promptly and minimizing production impact.

- Significant Cost Savings:

- Optimization of operations and reduced downtime translate to substantial cost savings. Remote diagnostics and updates further cut down on the need for on-site visits.

How it Benefits you

The Smart Supervisor Gateway is a versatile solution suited for a wide range of industries:

- Manufacturing:

- Essential for real-time monitoring and control of production lines, enhancing predictive maintenance, quality control, and operational efficiency.

- Energy and Utilities:

- Critical for remote monitoring and management of infrastructure, enhancing reliability and operational efficiency in energy and utility sectors.

- Oil and Gas:

- Perfectly designed for harsh environments and remote locations, providing real-time data processing and monitoring capabilities.

Some Practical Applications

- Predictive Maintenance:

- Real-time data analysis allows for early detection of potential equipment failures, enabling proactive maintenance and reducing downtime.

- Real-Time Quality Control:

- Continuous monitoring ensures immediate detection and correction of defects, improving product quality and reducing waste.

- Energy Management:

- Optimization of energy usage across operations results in significant cost savings and improved sustainability.

- Anomaly Detection:

- Advanced algorithms detect unusual patterns, prompting proactive measures to mitigate potential issues.

- Remote Monitoring and Control:

- Facilitates management of industrial processes from any location, streamlining operations across multiple sites.

- Data Synchronization and Storage:

- Built-in data storage prevents data loss during network outages, while synchronization features maintain data consistency with cloud servers.

- Protocol Conversion:

- Converts data between different industrial protocols, ensuring seamless integration of diverse systems and enhancing operational efficiency.

- Custom Scripts and Automation:

- Supports custom scripts for advanced data processing and automation, tailored to specific operational requirements.

Conclusion

The Smart Supervisor Gateway revolutionizes industrial automation, offering unmatched real-time data processing, robust security, and seamless integration capabilities. By addressing key challenges such as latency, data security, and scalability, it ensures efficient and secure industrial operations. Whether in manufacturing, energy, smart cities, or oil and gas, the Smart Supervisor Gateway provides the reliability and performance needed to elevate your operations.

Transform your industrial operations with the Smart Supervisor Gateway. Contact us today to learn how our advanced IIoT solutions can benefit your business.