HBK’s IO-Link solutions: addressing and solving customer challenges

Supported by leading companies in the field of sensor technology and automation, IO-Link now extends to hbk sensors for the digital measurement of mechanical quantities like force, load, and torque. As a future-proof technology, IO-Link is set to be the predominant interface for field-level sensors for many years ahead, providing customers with the future proofing they seek. Offering unparalleled cost savings and advantages by leveraging existing infrastructure and human resources, IO-Link technology not only minimises upfront investment but also maximises process efficiency, accuracy, and reliability, ultimately granting businesses a competitive edge through optimised operations and the lowest total cost of ownership (tco).

What is IO-Link?

IO-Link is a global industrial communications networking standard (IEC 61131-9) used for connecting digital sensors and actuators in the field-level to control level systems (i.e. PLCs). It is a bi-directional, point-to-point communication protocol that allows devices to exchange data with a control system and/or IT-Level application, providing detailed device diagnostics and enabling efficient parameter adjustments. This technology simplifies connectivity and enhances data availability, which leads to improved system diagnostics, increased effi- ciency, and reduced costs. An IO-Link system consists of an IO-Link master and IO-Link device (sensor or actuator) and an IODD (IO Device Description) file. With the advancement of Industry 4.0 and its focus on automation, decentralization and the requirement of gaining more information from production processes, manufacturers and system integrators are under continu- ous pressure to improve manufacturing efficiency, optimise production processes and increase productivity. Find out how HBK IO-Link solutions, ideally suited for industrial applications and efficient signal pre-processing, can also alleviate many of your challenges.

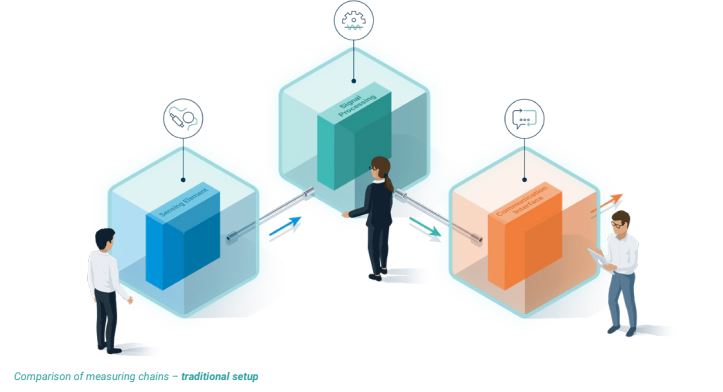

Keeping up with technology while keeping costs low

Traditionally customers have been required to purchase analog strain gauge based sensors as well as an additional amplifier to complete their measurement setup. However, the IO-Link solution eliminates the need for an external measurement amplifier by incorporating it either as an in-line amplifier, or directly integrating it within the sensor. This integration provides customers with a single unit that combines both the sensor and amplifier, simplifying your measurement chain and reducing costs.

Cost-effective, standardised cabling

In traditional setups, analog strain gauge based sensors require connection to a separate amplifier via a 4- or 6-wire shielded cable to protect the low microvolt-level signals from electromagnetic interference. The IO-Link solution, however, communicates at a robust 24 V level, eliminating the necessity for complex wiring, single shielded or even double shielded cables. This not only simplifies installa- tion but also significantly reduces costs, as IO-Link cables are standardised and far more affordable in fact over ten times cheaper than their analog, strain gauge based sensor counterparts.

In traditional setups, analog strain gauge based sensors require connection to a separate amplifier via a 4- or 6-wire shielded cable to protect the low microvolt-level signals from electromagnetic interference. The IO-Link solution, however, communicates at a robust 24 V level, eliminating the necessity for complex wiring, single shielded or even double shielded cables. This not only simplifies installa- tion but also significantly reduces costs, as IO-Link cables are standardised and far more affordable in fact over ten times cheaper than their analog, strain gauge based sensor counterparts.

Space-saving solution

Cabinet space is a valuable commodity in industrial settings. It requires space in expensive workshop areas, with costs escalating as cabinet size increases. The IO-Link solution addresses this issue by reducing the need for cabinet space. This is achieved through the use of IO-Link sensors that have built-in amplifiers, allowing for direct connection to decentralised IO-Link masters. These masters are typically positioned in close proximity to the sensors rather than inside the cabinet, further conserving space. This advantage is also realised when a Programmable Logic Controller (PLC) within the cabinet is equipped with integrated IO-Link master ports, requiring only the IO-Link cables to be routed into the cabinet.

Leveraging existing IO-Link infrastructure

Customers grappling with the complexity and cost of integrating multiple sensors and electronic components can take comfort in the simplicity provided by the IO-Link infrastructure. Those who have already adopted IO-Link sensors and masters can effortlessly enhance their systems by incorporating HBK IO-Link sensors using existing IO-Link masters, leading to a reduction in overall system costs. This also minimises the number of different sensor and electronic solutions within one machine.

IO-Link standardisation – easing the complexity of interface management

In today’s production environment, customers often grapple with the challenge of managing multiple inter- faces. IO-Link offers a unified interface technology that caters to a vast majority of sensor and actuator domains. This means that a single type of gateway can accommo- date about 90% of sensors and actuators, streamlining design and inventory management. Additionally, it reduces the level of expertise required from service and engineer- ing staff, making operations more efficient. HBK sensors require minimal integration effort because both the firmware and hardware are designed in full accordance to the smart sensor standard of the IO-Link community.

A technology that’s here to stay

Investment security is a paramount concern for customers who need assurance that the products they use will remain available, especially for servicing and repair. Employing a wide range of products and different solutions increases the likelihood of product discontinuation, and the total cost of ownership is also a critical factor when selecting components for machinery. IO-Link addresses these concerns as a standardised solution, which is widely accepted in the automation industry. With the number of IO-Link nodes rapidly increasing, it offers a unified standard that simplifies the previously varied analog and digital signal and connector landscape.

Intuitive commissioning and service through standardisation

A new era in sensing mechanical quantities – HBK ́s smart IO-Link sensors The integration of HBK IO-Link sensors signifies a trans- formative advancement in the utilisation of strain gauge based sensors. Gone are the days when manual parame- terisation of load cells and force sensors with mV/V scaling was fraught with errors due to incorrect inputs or the absence of production protocols. These innovative sensors deliver measurement values directly in standard units such as Newtons, kilograms, or Newton-meters. They come with the scaling information and measurement ranges already stored in the sensor, which is accessed in a standardised way by the IO-Link master and higher-level PLC systems, offering a ‘plug and measure’ capability. Furthermore, user-specific parameterisation can be efficiently managed at various levels, including the sensor, master, and PLC, thanks to the IO-Link Smart Sensors Profile, IODD, and the IO-Link solutions parameter storage and backup features.

Reduced training requirements

Reduced training requirements and simplified maintenance operations are key advantages of IO-Link technology. Traditionally, the complexity of strain-gauge based measurement chains demands personnel with specialised training in system integration and servicing, including skills in cabling, wiring, sensor scaling, and signal output. However, IO-Link simplifies this process significantly. With pre-stored sensor scaling information and streamlined parameterisation through the Smart Sensor Profile and IODD file, manual wiring is eliminated, and standardised M12 connectors for devices and masters reduce the training requirements for employees. Additionally, IO-Link’s standardised method for connecting all types of sensors within a machine simplifies both commissioning and servicing processes. This reduces service costs and effort, enabling technicians to work more efficiently with less specialized training.

Optimised workflow: achieving efficiency and flexibility

Addressing data overload, HBK’s IO-Link sensors employ domain-specific algorithms to pre-process measurement data. By transmitting only essential results, they simplify and reduce costs for customers. Additionally, the solution ensures compatibility across different PLC architectures, allowing flexibility in sensor and actuator choices based on needs, not just protocol constraints. IO-Link offers integration to all common PLC architectures, which allows for flexible machine concepts.

Reduced downtime, reliability and accuracy

HBK IO-Link sensors tackle critical challenges in the industry. Unlike analog sensors, they monitor health factors like temperature and sensor-specific load limits. Early alerts based on predefined limits during production help prevent costly machine breakdowns. For quality assurance and compliance, HBK’s IO-Link force and torque sensors store calibration data within the sensor itself, ensuring precise and fully traceable measurements. Additionally, these sensors offer highly accurate amplifiers and advanced scaling options, meeting diverse measure- ment requirements across applications. When combined with calibration data, these sensors can achieve significantly improved accuracy.

Reducing total cost of ownership

In the face of mounting macroeconomic challenges and intensifying market competition, machine manufacturers are compelled to seek solutions that reduce the total cost of ownership (TCO) of their machinery without sacrificing precision, quality, or overall machine lifetime. By leveraging the benefits of IO-Link the standard, manufacturers can enhance machine designs and achieve significant cost reductions, thereby addressing the general pressure to optimise expenses while maintaining high standards of machine performance.

IO-Link and HBK– the way forward

Investing in HBK sensors with IO-Link is not only a step towards modernising manufacturing processes but also a strategic move that promises a low total cost of owner- ship (TCO) and high return on investment (ROI). This technology enables instant cost savings across various levels, including component, related, and labour costs. By upgrading processes and utilising existing infra- structure and human resources, companies can gain a competitive edge. The broad HBK portfolio of IO-Link capable sensors spans multiple domains, reflecting our commitment to this enduring technology. As industries evolve towards smarter manufacturing, our extensive experience in sensor solutions drives product innovation through virtual, physical, and in-process testing across the product lifecycle. Moreover, HBK serves as a trusted supplier, offering technical consulting, learning opportunities through the HBK academy, and a global webshop. Our service and support network, powered by skilled engineers and technicians, ensures exceptional service at every phase of your testing and measurement projects, making an investment in HBK IO-Link sensors a secure, future- proof choice.