Optimize Your Power Consumption Through Remote Monitoring PDUs and RPPs

The Industrial Internet of Things (IIoT) generates a tremendous amount of data that also needs to be stored. Consequently, more and more data centers are needed to fulfill this growing demand for data storage management, increasing energy consumption in the process. At the same time, factories, supermarkets, and other high power consumption applications are also facing pressure to improve energy efficiency for their heavy-load equipment and devices. Data center operators and application owners need to figure out how to operate numerous servers and power-hungry equipment while optimizing power consumption. Power distribution units (PDUs) are used to control and distribute power to various equipment. Nowadays, intelligent PDUs that feature metering and switching capabilities from remote sites have seen significant market growth due to increasing remote monitoring demands. In fact, a recent industry report1 identifies the increasing demand for data center monitoring solutions as the key driver of PDU market growth. Monitoring PDUs in your application not only helps you optimize your energy usage—by recording daily power consumption for payment calculation and energy management—but also allows you to collect data about the status of your PDUs for device maintenance.

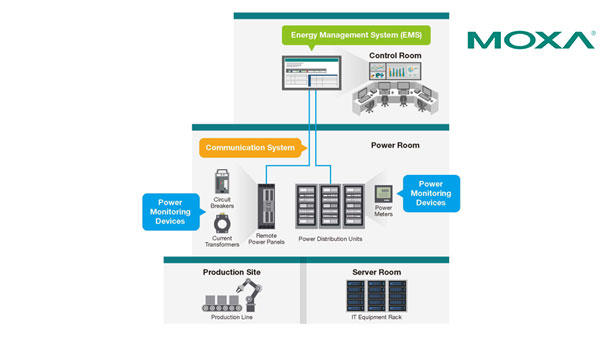

To reap the benefits of monitoring PDUs, an energy management system (EMS) needs to collect meter data from PDUs so that operators can control, monitor, and optimize the performance of the PDUs. In addition, remote power panels (RPPs) may also be used as an extension of PDUs to increase the power distribution capacity by providing extra circuits. Thus, it’s also important to monitor the circuit breakers and current transformers to ensure that power distribution through different circuits is under control.

It takes reliable connectivity between the EMS and power devices, such as PDUs and RPPs, to ensure smooth and optimized power distribution. Here are some tips you can consider to ensure reliable connectivity in between.

Retrofitting or Building New? Understand Your Development Stage

Once you decide to monitor the PDUs and RPPs in your application environment, how you go about enabling connectivity depends on your implementation plan. Besides connecting power meters, circuit breakers, and current transformers that might use different protocols and interfaces than your EMS, ask yourself the following questions to choose the right solution:

- Are you trying to retrofit existing PDUs or deploy a new one?

- Is there enough space for your wiring design?

- How many PDUs are you planning to connect to the network?

Your answers to the above questions will tell you whether you are looking for a single-port or high port-density connectivity solution. For example, if you have limited space for retrofitting your existing PDUs in a relatively small-scale application, a single-port connectivity solution may be the ideal option due its compact design. In contrast, high port-density connectivity solutions can help you save costs if you have sufficient space to deploy multiple new PDUs.

Minimize Your Effort on Installation and Maintenance

Choosing an easy-to-use connectivity solution can save you significant time and effort. In the installation stage, wiring can be painful when you are connecting dozens of PDUs to the same network. Check if your connectivity solution has features such as Ethernet cascading, which provides an efficient wiring solution across several PDUs and RPPs to the EMS located in the control center. When your PDUs and RPPs are up and running, your networking devices will still require backups and updates from time to time. If your connectivity solutions provide user-friendly software tools, it can take the headache out of device configuration and maintenance.

Enhance Your Operation Reliability

When unexpected network failures occur, meter data loss can lead to miscalculation of your power consumption, resulting in incorrect billing and incomplete power data for analytics. To enhance your power monitoring system reliability, you need to consider backup mechanisms from different angles. Start from the networking devices. Dual-power inputs and high EMI immunity are features that can protect your networking devices from electrical interference. Next, develop a redundancy mechanism for your network transmissions. There are various network redundancy features in the market. When considering these options, see if their recovery times are acceptable for your power monitoring application.

As a leading expert in industrial connectivity, Moxa has helped customers around the world develop smooth and reliable communication for their power consumption monitoring applications. Visit www.moxa.com and see how other companies develop communication systems for their PDUs and RPPs with Moxa’s solutions