Using tubular linear motors over ballscrew can improve productivity, simplify machine build, at reduced maintenance cost

ANCA Motion’s LinX® M-Series offers speed, accuracy, easy installation and maintenance

In the history of actuation and motor movement, technical progress brought the innovative development of linear motor technology, to build on the well-established foundations of ballscrew actuation and rack and pinion methods.

The long history of ballscrew, from as early as 1898, has secured a vital role in NC (Numerical Control) machine operation and production processes across an array of industries.

The goal of replacing sliding friction mechanisms with rolling friction led to first the concept of inserting balls between a male screw and nut, and then the early design and application in steering gears for the automotive industry in the 1940s and 50s.

These historical indirect drives continue to serve their functional purpose, but other, newer methods of creating linear motion are showing their benefits when it comes to accuracy, speed, safety, and lower maintenance burdens on owners.

Direct drive methods, which are simpler and can be superior in a lot of ways, are growing in popularity.

The early adopters for tubular linear motors were big semiconductor companies, which could invest big R&D budgets on a solution offering high speeds and sub-micron accuracy. Nowadays they are available to modestly sized businesses.

Both tubular linear motors and flatbed linear motors have vastly superior dynamic performance and longer lifetime compared to ballscrew options. A tubular linear motor is also a much simpler design, with only two moving parts (the shaft and forcer) and does not have to rely on intermediate components such as a gearbox to change torque.

When there is a need for speed

Limited by its rotary-to-linear translational mechanism, ballscrew methods are unable to achieve very high speeds and accelerations. Typically, ballscrew systems can only achieve a speed of 2m/second and 1.5G acceleration at best. Increased ballscrew speeds may be achieved by increasing the pitch, however this results in compromised positional resolution.

These issues are overcome when using tubular linear motors. Due to its direct-drive nature, LinX® M- series can achieve a maximum speed of up to 10m/second and over 30G of acceleration, with no impact on the positional resolution at all.

Quality and accuracy assured

Unlike ballscrews which translate rotatory motion to linear motion through the contact between thread and nut, LinX® provides direct-drive motion without any contact between forcer and shaft. This solves the challenges of backlash and reversal error associated with ballscews.

“In ballscrew systems, motion is created by direct contact between the surface of the nut and the lead,” explains Heng Luo.

“There will be some gap between the nut and the lead, otherwise the nut won’t move. So there has to be a gap, and there has to be backlash, and this can be corrected to some degree but never removed completely.”

The contact also means noise and dust are created. Switching to tubular linear motors and avoiding

this is an obvious advantage for cleanroom use.

ANCA Motion’s tubular LinX® Linear Motors consist of a shaft containing magnets and a forcer containing wound copper coils. The symmetric design results in zero attractive forces between the forcer and shaft, greatly reducing the loading requirement on support bearings.

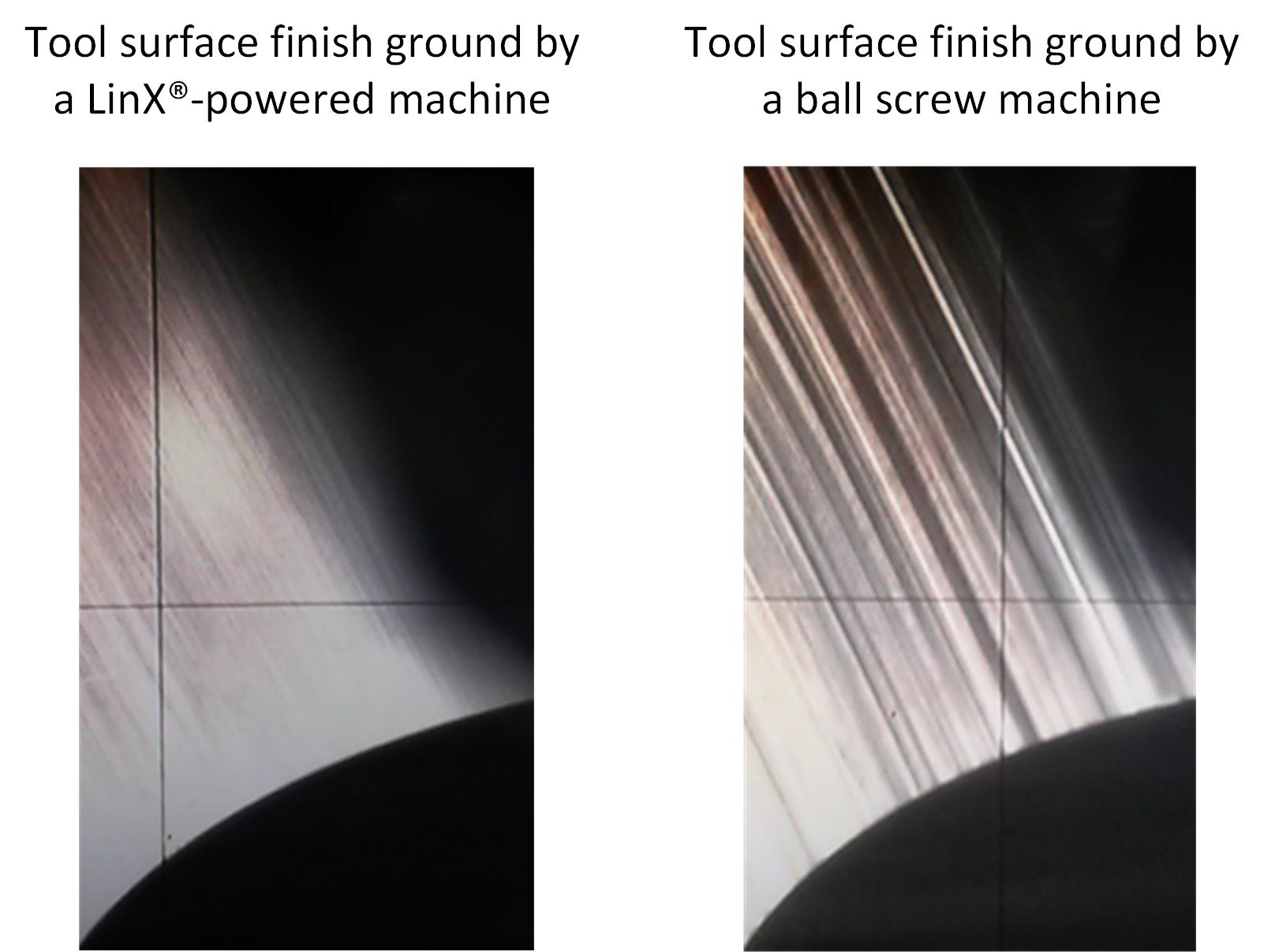

Figure 1 demonstrates the significantly improved tool surface finish ground by a LinX® powered machine.

Reduce maintenance with easy to install retrofits

Similar to a spring, ballscrew actuators are sensitive to jerk and lack the nimbleness of tubular linear motors. The contact between the nut and screw means lubrication is essential and causes wear and performance degradation over time.

ANCA Motion’s LinX® M-Series is specially designed to be close in form to ballscrew systems, offering easy substitution for those who are ready to make the change.

Retrofitting tubular linear motors is ideal for ballscrew, providing a more streamlined option, compared to the more challenging swap from flatbed motors. The structure for flatbed is totally different, requiring more costly machine redesign.

“When you install a ballscrew motor into a machine, the tolerance that you need to achieve for a stroke will be much more stringent than for a tubular linear motor. You will need to ensure 20um to 30um of tolerance along the full stroke which needs to be carefully managed when machines are assembled, in other words – a longer build time,” explains Heng Luo, Product Manager at ANCA Motion.

“Tubular linear motors have a big advantage here, because of the 1 mm air gap between the shaft and the forcer, there is a very relaxed tolerance requirement. Compared with its ballscrew counterpart, using tubular linear motors could reduce the machine build time by up to 50%.”

Ongoing maintenance requirements are also reduced as linear motors overcome the issue of backlash suffered by ballscrew actuators. A simple construction ensures machine manufacturers can greatly simplify installation, reduce maintenance and extend machine life.

Besides being wear-free due to the one-millimetre air gap between forcer and shaft, the M-Series offers peak resolution of 10 micrometres, peak velocity of 10 metres per second, and peak force of up to 1200N.

With no backlash, no wear, a high level of dynamism and low level of maintenance, the M-Series represents immediate gains in manufacturing productivity. The LinX® M-Series also has a failure rate under 0.03 per cent.

A history of innovation with the ANCA Group

ANCA Motion’s linear motors were originally developed for sister company ANCA CNC Machines’ FX Linear and MX Linear machines. ANCA is a leader in CNC tool grinding technology, with a series of world firsts since beginning in 1974. The LinX® M-Series has been developed within a culture of world-class engineering, developing machine tools where micron-level precision is valued.

An international network of 125 engineers in strategic locations is on hand, offering fast, reliable support.

Fore more details Please contact

ANCA Motion

1 Bessemer Road, Bayswater North,

VIC, 3153 Australia

T: +61 3 9751 8900

India T: +91 636 644 9980

www.ancamotion.com

sales@ancamotion.com