Linear progression: going beyond common actuation methods for greater productivity

From harsh environments to automated warehousing – Tubular linear motors offer significant benefits

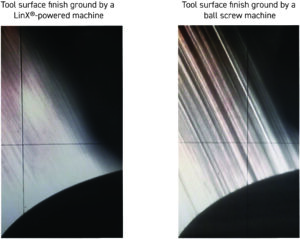

There is stored energy and there is kinetic energy, or movement. Motors turn the first into the second. As with everything else, ways to create movement have evolved. One comparatively recent kind of actuation, tubular linear motion, is gaining in favour in applications as diverse as machine tool building, factory automation, packaging, printing and material handling. In this article, we will look at the three most common kinds of actuation compared to tubular linear motors, which are gaining currency in manufacturing, logistics and elsewhere due to their precision, speed, efficiency and other benefits. For many businesses, energy consumption, and safety of their workforce are high priorities, and any way to lift the productivity of a workplace and the safety of its staff deserves consideration. ANCA Motion is an Australian developer and manufacturer of motion control systems, hardware, and software including for its sister company, ANCA CNC Machines. ANCA Motion as a global company has offices in key locations including China, Taiwan and India. The India branch has after sales support via a local field application engineer. ANCA has used LinX® tubular linear motors for its globally- renowned tool and cutter grinders since 2014, introducing them in their FX Linear and MX Linear tool grinding machines. Customers have welcomed the better surface finish, increased efficiency and improved reliability gains at reduced operating cost in their machines incorporating LinX® tubular linear motors within the precision toolmaking industry, where micron-level resolution, as well as throughput, is important.

Pneumatic

Pneumatic actuators have a history going back roughly to World War Two. Today they’re a factory staple, used to quickly (and noisily) move between two set points. They’re a major user of electricity in factories, and according to one estimate, using compressed air to perform a task directly takes 10 times the energy of using electricity directly, due to the creation of waste heat. Though inefficient, pneumatics are well-understood and widely-used. Depending on the size of a factory, getting compressed air to a source might require multiple compressors and/or a complicated reticulation system. Leaks throughout such a network are expensive. One major bottleneck they can create is their inflexibility. Recalibrating air pressure between different batches can sometimes take hours.

ANCA Motion’s LinX® motors, on the other hand, work on servo- based, closed-loop control, and changing set points is quick and painless, meaning minimal time between one batch and another. They have an integrated position sensor with 10um of resolution, eliminating the need for an external encoder and simplifying system integration, and also allowing for higher quality and throughput. The saving on energy costs quickly offsets the upfront cost, and a payback period versus pneumatics is generally 18 months.

Ballscrew

At more than a century old, ballscrew motion goes back even further than pneumatics. It is still around, and used in a broad set of applications, from power steering to moving robotic arms.

It is an indirect drive method, using nut and thread to turn rotational movement into linear movement. Ballscrew motion has its usefulness, proven by its longevity, but also its shortcomings. It is unable to accelerate and decelerate quickly. The contact between moving parts creates wear and friction, and requires lubricants, which can become a source of contamination. Wear also leads to increased maintenance costs and a decrease in performance over time. Another source of bother is backlash, or lost motion, which is caused by the necessary gap between the thread and nut. LinX® motors are much more nimble in comparison, with no backlash due to the direct drive nature and resulting zero friction between their forcer (a sleeve with copper coils) and shaft (a sealed stainless steel tube containing magnets.) The lack of friction means less wear and better longevity, and better quality for tools or whatever other product they are involved in making. LinX® motors are also capable of achieving velocities as high as 10 metres per second, meaning a major boost for productivity.

Flatbed linear

Flatbed linear motors (often simply called linear motors) are regularly described as an unrolled version of a rotary electric motor, with the rotor (containing magnets) the stationary part and the forcer (containing coils) the moving part. Non-factory examples include maglev trains and railguns. Within industrial settings, such linear motors have found their high precision, velocity and force abilities applied to scenarios such as material handling and in machine tools. Another way they improve on ballscrew motion is by having no backlash or reversal error. A downside to this kind of direct drive motor is its inability to be used in harsh environments. Mechanical stress and heat are also generated due to the attractive forces between the rotor and forcer. This can require use of a separate chiller to control, which in turn increases the total cost of ownership. The strong downforce causes extreme wear of the motor’s railings and it requires frequent replacement.

The answer to this, tubular linear motors, and offers increased lifespan due to no contact between forcer and shaft, with zero attractive forces due to LinX® motor’s symmetrical design. Also, Tubular linear motors makes full use of magnetic flux and has greater thermal stability. These features make it suitable for use in harsh applications. This leads to a lower total cost of ownership and better precision.

Australian engineering heritage, global reputation

ANCA Motion’s linear motors were originally developed to give ANCA CNC Machines an edge in a highly competitive global industry. ANCA is a world-leader in CNC tool grinding technology, with a series of world firsts since beginning in 1974. It exports almost all of what it makes at its Melbourne headquarters. The LinX® series has a heritage in tool manufacture, but has a growing list of customers the world over, and are used across various industries in diverse applications These include pick and place, labelling, pressing, reject sorting, stacking, transfer, line distribution, and many other material handling applications within automated warehousing.

Besides LinX®, the company offers a range of servo drives, human- machine interfaces and control systems. ANCA Motion has decades of experience in developing motion control solutions and partners with customers to develop custom solutions. This is supported with a local team of engineering, sales and service experts ready to help expand Australia’s sovereign manufacturing capability. Besides custom motors, ANCA Motion supplies standard LinX® linear motors in two ranges: M-Series (continuous force of 80 N to 287 N, peak force of 1200 N) with IP 66 rating and S-Series (continuous force of 335 N to 630 N and peak force of 4270 N.) with IP 67 rating.

At ANCA Motion we offer flexibility, reliability, innovation and precision – providing solutions that give our customers a competitive edge. Our focus and passion is designing and manufacturing flexible control systems; specialising in high precision solutions for CNC machines. Our hardware and software is tailored to an OEMs exacting requirements. Continuous support and innovation throughout the life of the product allows us to deliver world-class products and service. ANCA Motion is part of the ANCA group which also consists of ANCA CNC Machines, ANCA Sheet Metal Solutions and ANCA Engineering Solutions. ANCA was founded in in 1974 in Melbourne, Australia where the company still has its global headquarters. ANCA Motion has offices in India, China, Taiwan, Europe and the United States of America.