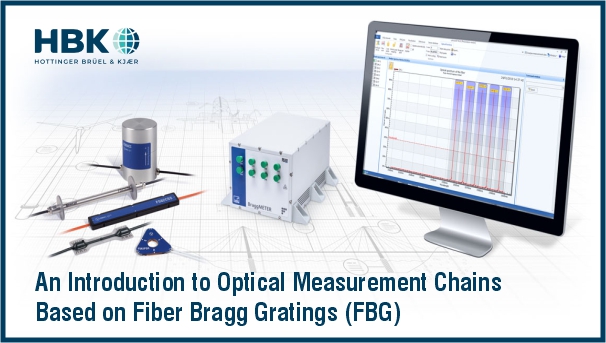

An Introduction to Optical Measurement Chains Based on Fiber Bragg Gratings (FBG)

This article aims to help system integrators and engineers choose the right components for multi-physics optical monitoring solutions. This is crucial, as all major structures – such as bridges, buildings, pipelines, and tunnels – are exposed to factors that cause strain and degradation. Without reliable and accurate monitoring of strain, temperature and other physical parameters, malfunctions and structural issues might not be detected, resulting in disasters.

In the following, we’ll discuss structural health monitoring (SHM) as a discipline, and we’ll show you how a typical optical Fiber Bragg Grating (FBG) based measurement chain – hosting several sensors in one optical fiber, interrogators, and PC software – can easily be designed.

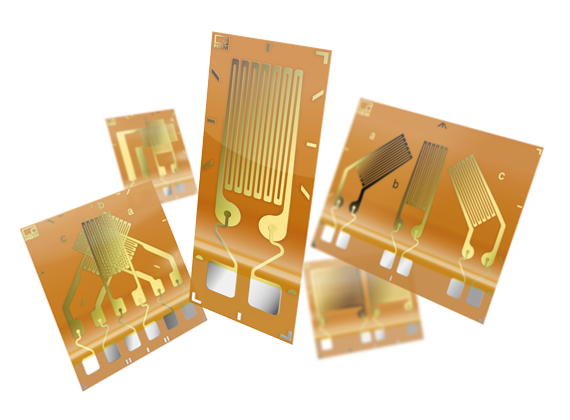

Use of Conventional Resistive Strain Sensors

Since the 1940s, the resistive strain gauge has been the benchmark for structural strain monitoring [9]. But certain limits come along with resistive strain gauges and sometimes hinder easy and reliable measurement.

For example, the number of electrical cables needed can be a challenge. This is because long cables are costly, and lots of them can become difficult to manage when used in large scale structures with many measurement spots [10], despite the existence of technical solutions for measuring electrical strain over distances up to several hundred metres, and to both technologies [4].

Fiber Bragg Grating Technology: An Innovative Solution for Structural Health Monitoring

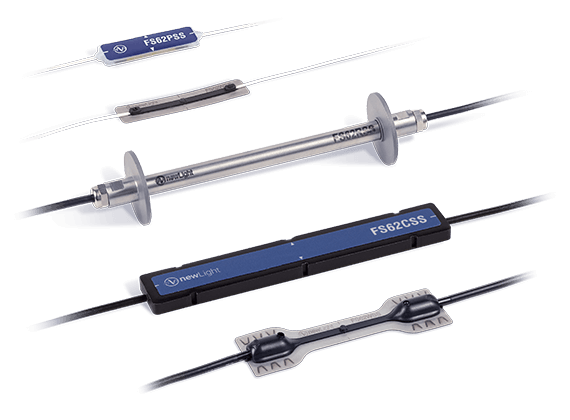

Optical sensors that are based on Fiber Bragg Grating (FBG) technology offer an attractive alternative to conventional electrical measurement chains.

This is because FBG technology has advantages such as multi sensors in a single optical fiber, overall lightweight passive design, and low attenuation, which allows long distance installation. This technology is also immune to electromagnetic interference (EMI), and sensors are more environmentally stable than electrical strain gauges (so they can withstand harsh conditions). They’re also competitively priced when it comes to a medium to high channel count and total cost of ownership [12, 13].

The benefits of FBG-based sensors:

- Immune to electromagnetic noise interference (EMI)

- Low attenuation and can be installed over long distances

- Can have several sensors on the same line. This reduces cable length and complexity, and also simplifies installation which is more cost-effective

- Can withstand harsh conditions, minimizing the need for complex or expensive protection solutions

- Long-term signal stability (no drift) with an absolute zero reference (related measurements even if scattered in time)

FBG Technology Application Fields

Thanks to the fact that it can be easily used with your supplier’s software, and is also integrated into any individual PC, FBG technology has acquired a large market share over time. It’s now used in a wide range of sensing applications [13].

For instance, it’s used in different health monitoring applications in civil engineering, including road and railway infrastructure, but also in geo-structures, oil and gas, hull monitoring of vessels in the marine industry, aerospace structures, and automotive temperature validation.

More advantages of FBG technology:

- Multiplexing many and even different sensors in a single fiber. All sensors will then come along with different wavelengths, reducing the amount of wiring needed for the sensing network.

- Long-term signal stability and system durability, even with high vibration loads. Sensors are unlikely to fail on roadways and bridges where increasing traffic demands cause structural wear and tear.

- Distance and cable length have minimal effect on measurement accuracy. Since FBG sensors experience low attenuation, the data is always reliable. And this is true even if the data acquisition system is several kilometres away from the furthest sensor.

- Optical fibers are thinner and lightweight when compared to copper cable.

- And, as mentioned above, FBG technology is not at all affected by electromagnetic interference (EMI) or radio frequency interference (RFI), which allows a sensor installation near safety critical parts such as railway overhead lines, and pantographs.

- These FBG sensors can also be used in highly explosive atmospheres and under other harsh conditions.

Optical Measurement Chains: The Complete Package For SHM

For a complete optical measurement chain, having the right sensor is only one third of the solution. You also need the right optical interrogator, and the right software in place to get overall reliable results.

And these three parts – sensor, interrogator, and software – complete your optical measurement chain.

In short, the sensor is what measures or ‘senses’ strain, temperature, acceleration, force or even tilt. The optical interrogator (the second component in the chain) is also known as a data acquisition system. It’s an optoelectronic instrument which ‘reads’ the FBG sensors. And the software is what allows you to view, record and analyse your measurement data.

So what should you look for when choosing these components?

So what should you look for when choosing these components?

Conclusion

Optical sensors based on Fiber Bragg Grating technology have many advantages over conventional resistive strain gauges. Both sensor types can also complement each other in various applications, from civil infrastructure and aerospace, to lab testing and energy.

But to make use of these advantages, you need to choose the right sensors, interrogators and software for your optical measurement chain. Our hope is that this brief primer can help engineers and system integrators make the right decisions when it comes to accurate and reliable strain measurements.