SLH Solution: versatility precision, and optimal performance with C-frame presses

VERSATILITY AND ACCESSIBILITY: THE ADVANTAGES OF C-FRAME PRESSES

C-frame presses are essential tools in metal fabrication, valued for their versatility and accessibility across various manufacturing processes. These presses are commonly employed in applications such as punching, cutting, bending, forming, soldering, spot welding and riveting Additionally, they play a crucial role in assembly and joining processes.

- Sheet Metal Stamping: Easy Handling and Quick Tool Changes: C-frame presses are ideal for punching holes or shapes in sheet metal materials. Their open design facilitates easy handling and quick tool changes, significantly boosting efficiency and productivity in high-demand production environments.

- Precise Component Assembly: These presses are perfectly suited for press-fitting bearings, bushings, or other components into metal parts. They provide the necessary force for precise assembly, while integrated precise measurement technologies ensure rigorous quality control.

- Efficient Riveting: A Reliable Joining Process: C-frame tools can also be used for riveting processes, where metal sheets are joined by deforming and inserting a rivet. This process ensures a strong and durable junction, which is essential for many industrial applications.

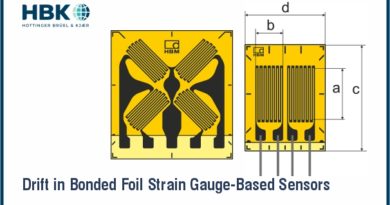

FORCE MEASUREMENT WITH STRAIN

Utilising extensometers for measuring forces on a C-frame is a proven method that enables precise force measurement and control. This approach offers numerous benefits, including ease of integration to real-time monitoring.

- Structural Integration and Optimal Precision: The technique of measuring forces on a C-frame using an extensometer allows for easy integration with just two screwing points and, effectively upgrading an existing machine element into a process-related sensor. This reduces design and integration efforts while providing flexible signal output for control systems.

- Real-time Monitoring and Cost-effectiveness: Strain gauge sensors enable continuous real-time monitoring of applied forces, which is crucial for process control and optimisation. Additionally, installing these sensors is often more economical than other force measure- ment methods, while still offering high precision and reliability.

- Robustness and Durability in Industrial Environments: The SLH700 strain gauge is designed to be robust and durable, capable of operating in harsh industrial environments due to its hermetically sealed design and IP68 rating. This ensures long-lasting and reliable performance even in the most demanding conditions.

- Very Low Restoring Forces with New Design: Strain sensors need to be stretched by the structures they are mounted on, with the restoring force at the nominal measuring range specified in Newtons. The new SLH sensor features a restoring force five times lower, allow- ing it to be used on lighter construction elements and opening up new application possibilities.

- Custom Calibration and Adjustment: SLH 700 can be calibrated to account for the specific properties of the C-frame and the materials used. Teach in routines allow to adjust analog output signals according to a refer- ence. This allows them to be adapted to the specific requirements and conditions of each application, further increasing measurement accuracy.

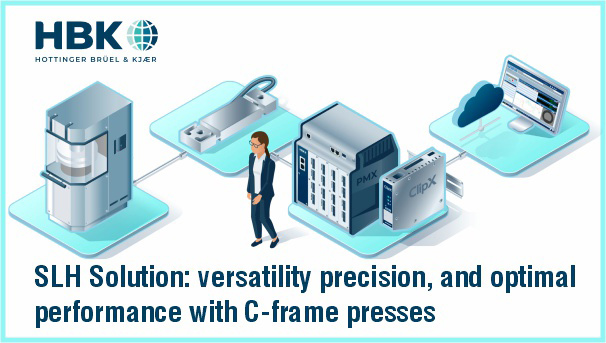

COMPREHENSIVE FORCE MEASUREMENT SOLUTIONS

HBK offers comprehensive solutions for efficient force measurement, leveraging the advanced SLH 700 strain gauge and a wide range of internal and external amplifiers, terminals, modules, and electronic devices. Designed to meet the rigorous demands of industrial applications, these solutions ensure seamless integration, maximum connectivity, and user-friendly operation.

- Seamless Integration and Maximum Connectivity: HBK’s precision solution, featuring the SLH 700 strain gauge, is complemented by a comprehensive range of terminals, modules, and electronic devices. These devices are designed to meet the stringent require- ments of applications in demanding production environ- ments. With a wide array of industrial interfaces and flexible software solutions, HBK devices ensure seamless integration and maximum connectivity. Their user-friendly design facilitates simple configuration, real-time data analysis, and optimised process control.

- Intuitive Software and Flexible Options: HBK exceeds expectations with its intuitive and reliable software, PanelX, along with various flexible options tailored to specific needs. Our integrated web servers, APIs, PWAs, and mobile applications provide smooth connectivity and precise control over your processes.

COMPREHENSIVE SERVICES: FROM INSTALLATION TO RECALIBRATION

The SLH sensor represents a remarkable advancement in force measurement for industrial applications, combining robustness and user-friendliness at a reasonable cost. To meet diverse industry needs, HBK offers comprehensive support from initial installation to on-site recalibration, ensuring optimal performance and trouble-free operation. HBK’s on-site support during installation and commission- ing ensures seamless integration of the SLH sensor in any industrial environment, minimising downtime and maxim- ising operational efficiency from the start. Regular calibration and maintenance visits by qualified technicians maintain the sensor’s accuracy over time, ensuring it consistently operates at peak performance levels.

A COMPLETE AND RELIABLE SOLUTION FOR INDUSTRIAL NEEDS

HBK provides a complete and reliable solution tailored to the specific needs of OEMs and end-users, facilitating efficient and cost-effective modernisation of industrial applications.