Making Filling Processes more Productive and Efficient

INTRODUCTION

By digitizing manufacturing processes, the Industrial Internet of Things (IIoT) can lead to great efficiency and productivity gains in the food and packaging industries.

Digital weighing technology in particular offers enormous potential for determining filling quantities quickly and precisely, which can lead to major savings – in some cases, several million Euros annually – as demonstrated by the example of a coconut milk producer in Shanghai. Previous analog weighing technology can also be digitized easily and reliably using transducer electronics and integrated on a single platform. Companies in the food and packaging industries are required to comply with the provisions of the EU prepackaging directive 76/211/EEC. The German prepackaging regulation (§ 22 FPackV) contains clear requirements regarding this: on average, the quantity must not be less than the nominal prepackaging capacity.

This means that, in practical terms, the producer is always free to overfill, but of course including less than the indicated quantity is critical. For example, if chocolate bars need to weigh 100 g, then only 2% of the bars can be lighter than 95.5 g and none lighter than 91 g. The result of this strict regulation is that many food producers work with expensive overfilling. This can add up to major additional costs, especially with premium products such as olive oil, ice cream and cosmetics. Underfilled products are also rejected, which results in more expense, additional processes and the associated costs. These inaccuracies can be prevented with a more precise, reliable weighing technology as early as the filling and metering phase and no later than at the checkweighers at the end of the production line.

IIOT DEMANDS DIGITAL WEIGHING TECHNOLOGY

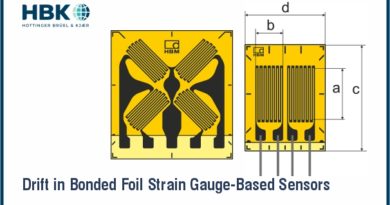

IIoT offers considerable potential for the food and packaging industries in particular with digital weighing technology capable of boosting efficiency and productivity. The reason for this is that the more precise the weighing technology, the greater the productivity of filling processes and the less overfilling. The load cell is the crucial component in powerful packaging machines. It is the core of dynamic weighing and packaging processes. Until now, manufacturers of checkweighers have relied on load cells that work on the principle of electromagnetic force compensation (EFC). They have previously outperformed other load cells based on strain gauge (SG) technology with high precision. At the same time, however, they are expensive, susceptible to problems and very complex to put in operation. Because of this, HBK has continually developed its SG-based load cells such as the

IIoT offers considerable potential for the food and packaging industries in particular with digital weighing technology capable of boosting efficiency and productivity. The reason for this is that the more precise the weighing technology, the greater the productivity of filling processes and the less overfilling. The load cell is the crucial component in powerful packaging machines. It is the core of dynamic weighing and packaging processes. Until now, manufacturers of checkweighers have relied on load cells that work on the principle of electromagnetic force compensation (EFC). They have previously outperformed other load cells based on strain gauge (SG) technology with high precision. At the same time, however, they are expensive, susceptible to problems and very complex to put in operation. Because of this, HBK has continually developed its SG-based load cells such as the

FIT7A. This newly developed load cell ensures precision and high speed for processing measurement data as well as easy operation, combined with significant savings in costs compared to EFC load cells. The FIT7A load cell has been optimized for checkweighing. It has a very high natural resonance, which means its settling time is very fast. The running-in behaviuor after power-on is also negligible and with the 24-bit analog-to-digital converter and carrier frequency, the load cell provides measured values with low noise and high resolution. Together with the integrated filters and processes for determining dynamic measured values, it contains everything necessary for dynamic weighing without the requirement of an additional PLC and weighing electronics. This makes it possible for a checkweigher with the FIT7A load cell to achieve a standard deviation of only 0.1 g per 10 kg of nominal weight. Depending on the checkweigher design and nominal weight, 100 to 400 measurements per minute can also be implemented.

DIGITAL LOAD CELLS OFFER THE FOLLOWING ADVANTAGES OVER EFC LOAD CELLS

•Increased output and reduced overfilling in high precision applications where EFC load cells may be too expensive

•Internal filters and inputs/outputs making an additional PLC obsolete

• A rugged design ensuring fewer failures

• Plugs enabling fast and easy replacement

•Integrated overload protection that can prevent the load cell from getting damaged by physical forces

• Hygienic, due to smooth stainless steel surfaces

• Active temperature compensation, enabling less temperature drift and a negligible running-in behaviour after power-on

ADVANTAGE OF THE GRAVIMETRIC FILLING PRINCIPLE

Digital load cells also make it possible for food producers to use the gravimetric filling principle. It leads to considerably more accurate filling results compared to the volumetric approach (flow measurements) or filling by filling height. The principle of gravimetric filling is superior especially

when high accuracy is essential or when it comes to microbiologically sensitive products. This is because tolerances in container volume and

different physical properties of the product (proportion of particles, viscosity, conductivity, number of gas bubbles) do not affect the filling result.

Weight-controlled filling provides optimum hygienic conditions and also reduces foreign particles because the sensor does not come in contact with the filling product.

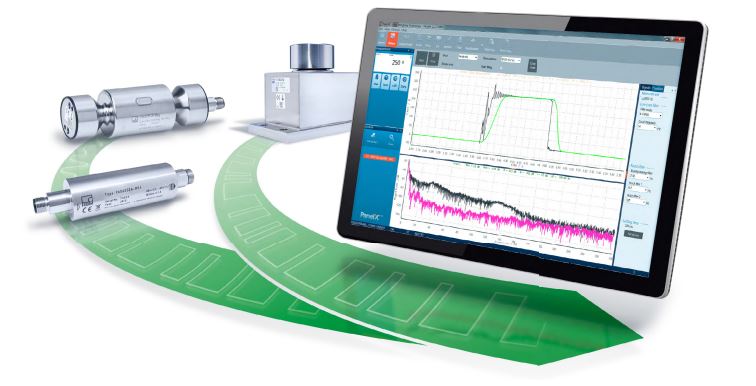

ONE DIGITAL PLATFORM FOR ALL LOAD CELLS

HBK has developed the PanelX software as a digital platform to integrate both digital as well as analog load cells based on the gravimetric filling principle into machines and processes in an optimal and user-friendly manner. Users can easily paramatrize and configurate checkweighers, dosing systems and multi-head combination weighers with the PanelX software. The ultimate goal is to optimize and improve your weighing system. A wide range of SG-based load cells can be configured easily with uniform command sets, which greatly reduces effort, cost and susceptibility to errors. In addition, a PLC is no longer needed with PanelX and the digital I/Os of the load cells and weighing electronics. If a control unit is used nevertheless, PanelX command sets can be transferred to the PLC. Other advantages of this digital platform include visual realization of measurement and control signals as well as extensive analysis functions, such as frequency analysis. The analysis functions are also helpful for maintenance and service, and even for finding errors in case of faults that are not caused by the load cell itself but are visible in the measurement. Extensive online help for functions, interfaces and command sets is already integrated into the software via a web browser. The PanelX user interface is intuitive, helping to save time and money. At the same time, the software taps the optimization potential of weighing technology applications, thereby increasing the overall performance.

PRACTICAL APPLICATIONS FOR DIGITIZED WEIGHING TECHNOLOGY

A large number of load cells can be configured and monitored with PanelX. Suitable digital and analog SG-based load cells can be configured and monitored for almost any application. That includes the analog load cell, PW27, which is certified by the European Hygienic Engineering & Design Group (EHEDG). It is specially designed for use in weighing systems for the beverage, food, pharmaceutical and bio industries. As a hermetically sealed load cell (IP68/IP69K) made of food-compatible stainless steel, it is insensitive to the cleaning methods used in the food industry and is designed so that no detergent residue remains on or in the measuring body.

A large number of load cells can be configured and monitored with PanelX. Suitable digital and analog SG-based load cells can be configured and monitored for almost any application. That includes the analog load cell, PW27, which is certified by the European Hygienic Engineering & Design Group (EHEDG). It is specially designed for use in weighing systems for the beverage, food, pharmaceutical and bio industries. As a hermetically sealed load cell (IP68/IP69K) made of food-compatible stainless steel, it is insensitive to the cleaning methods used in the food industry and is designed so that no detergent residue remains on or in the measuring body.

HBK has also developed PAD digital transducer electronics to make use of the advantages of digitization with analog load cells. Its functional scope is nearly identical to that of the FIT5A and FIT7A digital load cells. PAD can be connected to all analog load cells. For example, the hygienic load cell PW25 or the hermetically sealed heavy duty load cell PW29 with PAD can be digitized and then configured with PanelX. A compact stainless steel enclosure protects PAD against liquids and adverse environmental conditions up to equipment protection level IP68/IP69K. With a measured value

HBK has also developed PAD digital transducer electronics to make use of the advantages of digitization with analog load cells. Its functional scope is nearly identical to that of the FIT5A and FIT7A digital load cells. PAD can be connected to all analog load cells. For example, the hygienic load cell PW25 or the hermetically sealed heavy duty load cell PW29 with PAD can be digitized and then configured with PanelX. A compact stainless steel enclosure protects PAD against liquids and adverse environmental conditions up to equipment protection level IP68/IP69K. With a measured value

resolution of up to 5,120,000 digits for 2 mV/V and complete measurement signal conditioning with selectable or automatic filters, PAD works precisely even with strong vibrations. The transducer electronics can be conveniently integrated into different system environments using the RS485 and CAN open interfaces.

That makes it possible to visualize and analyze dynamic filling and dosing applications in harsh environments, and if necessary re-regulate immediately during the process. PAD is the plug & play connection for analog force transducers and load cells in the IIoT. As a next step towards IIoT, HBK developed the DSE-HIE weighing electronics. This is also packed in IP69K approved stainless steel and complies with EHEDG regulations, which is a must in the food industry to clean the aseptic machine. Furthermore it comes with selectable interfaces PROFINET, EtherCAT or Modbus-TCP. The whole setup of the amplifier as well as the filling, dosing and checkweighing can be done via the integrated DSE webserver. Ten integrated parameter sets can store ten different setups for diffents production setups, switched by a PLC. And if the user requires a PC-based control, DSE offers an API (Advanced Programming Interfavce) to integrate DSE into customer software.

That makes it possible to visualize and analyze dynamic filling and dosing applications in harsh environments, and if necessary re-regulate immediately during the process. PAD is the plug & play connection for analog force transducers and load cells in the IIoT. As a next step towards IIoT, HBK developed the DSE-HIE weighing electronics. This is also packed in IP69K approved stainless steel and complies with EHEDG regulations, which is a must in the food industry to clean the aseptic machine. Furthermore it comes with selectable interfaces PROFINET, EtherCAT or Modbus-TCP. The whole setup of the amplifier as well as the filling, dosing and checkweighing can be done via the integrated DSE webserver. Ten integrated parameter sets can store ten different setups for diffents production setups, switched by a PLC. And if the user requires a PC-based control, DSE offers an API (Advanced Programming Interfavce) to integrate DSE into customer software.

PRACTICAL APPLICATIONS FOR DIGITIZED WEIGHING TECHNOLOGY

Two of the following examples from the food industry in France and China show how digital weighing technology operates efficiently and productively, saving considerable costs. The considerably greater precision of the gravimetric filling process made it possible to reduce safety overfilling by a few grams per bottle. With a production volume of about 100,000 bottles per day, that means that coconut milk producer Shanghai Dairy Milk saves several million Euros a year. Equipped with the SG-based load cell FIT7A, it meets the special requirements of the food industry such as being completely covered in foam or being cleaned with a powerful stream of water. With an equipment protection level of IP66 and its watertight, hygienic plugs, the FIT7A offers optimum preconditions for these requirements.

THE KEY TO GREATER PRODUCTIVITY

Companies in the food and packaging industries can benefit disproportionately from IIoT and the digitization of weighing technology it offers as demonstrated by practical applications. Digital Strain Gauge based load cells are now comparable in precision to EFC load cells and they are cheaper, more rugged, easier to install and more durable. A uniform, intuitively operable digital platform not only simplifies the configuring of digital load cells, it also makes it possible to digitize analog load cells (as required for sensitive hygienic areas) via transducer electronics. That makes it possible to use digital weighing technology for almost any application in the food industry within or at the end of the filling process, and to readjust the process if

necessary. Compared to EFC technology, SG-based weighing technology offers significantly greater efficiency and productivity with considerably lower costs.

IIOT OFFERS CONSIDERABLE POTENTIAL FOR THE FOOD AND PACKAGING INDUSTRIES

HBK YOUR WEIGHING PARTNER FOR MORE THAN 65 YEARS

Whether used in industrial, hygienic, static, or dynamic weighing applications, HBK components offer a flexible modular kit enabling you to design the optimal solution for your purpose. These include: combined load cells, weighing modules, mounting aids, and other accessories with state-of-the art electronics and specialized software to form your dedicated measurement chain. HBK, as a component manufacturer, offers an independent

solution not purchased from a competitor. You are guaranteed legal compliance, and the necessary precision for increased efficiency in terms of financial and production or plant viability. Explosion-proof, hygienically designed, and EMC-tested products are available, as well as a global network of experts who can support you.

For more information, visit:

www.hbkworld.com/en/solutions/weighing