ANCA motion’s EtherCAT pendant is unique to the market – a practical and portable option that solves user challenges with seamless integration

The customisable, lightweight pendant is easy to operate for optimal user experience through simple plug and play.

When it comes to Human Machine Interfaces (HMI) – users are looking for smart, simple, and seamless integration. The key trends are effortless communication; functionality that makes sense for end- users; and a move towards portable interfaces that allow for more freedom when operating powerful and advanced machinery. Outside of manufacturing, the trend for wearable technology mirrors the need for gadgets that keep us mobile.

ANCA Motion applied their vast industry experience to design the AMI 5000 handheld remote pendant that boasts market leading features for EtherCAT® control systems in a portable, lightweight machine control interface. In fact, their solution is entirely unique to the market.

Joe Sheehan, Senior Automation and Controls Engineers, ACE at SpaceX said: “[I’m] really loving how nicely these pendants integrated into our EtherCAT master. It was as close to plug and play as it gets. Bravo!”

The rise of EtherCAT

Networking has become an essential component of smart manufacturing, with increasing demand for automation across industry verticals. The industrial Ethernet market surpassed 40 billion (USD) in 2020 and continued growth is expected with over 15% CAGR from 2021 to 2027.

Within this market EtherCAT is gaining popularity among machine builders and system integrators due to its swift response time, ease of use, cost effectiveness and exceptionally flexible solutions.

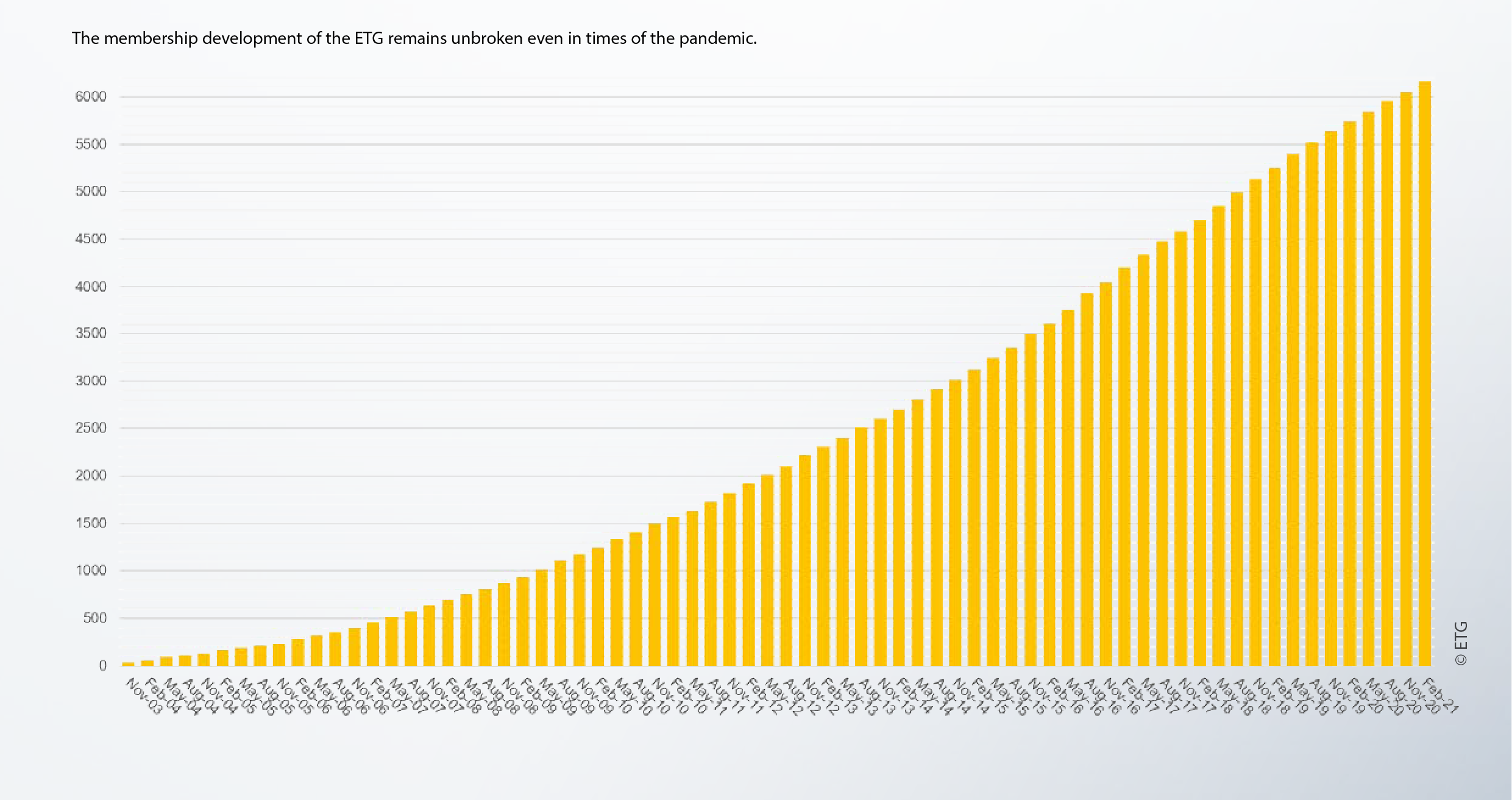

The membership development of the EtherCAT Technology Group remains strong even during the COVID. Available at: https://www.pc-control.net/pdf/022021/etg/pcc_0221_etg_sales_e.pdf

EtherCAT is a real-time Industrial Ethernet technology that is suitable for hard and soft real-time requirements in automation technology, in test and measurement, and many other applications. With more than 6000 member companies from more than 60 countries embracing this solution, the use of EtherCAT is increasing. With a history less than 20 years, the high response times offered by EtherCAT are seeing manufacturers switch from existing protocols. Adaptable and practical, EtherCAT technology controls power plants, semiconductor applications, baggage sorting systems, mobile robots, test stations as well as racing and flight simulators.

ANCA Motion’s EtherCAT pendant has been designed with both the OEM and the End User in mind

ANCA Motion’s EtherCAT pendants bring together a heritage of motion control and automation design with a targeted and mobile solution. Integration to an EtherCAT host system is a complicated and time-consuming exercise that is prone to connection issues as it is usually done through IOs. These solutions rely on indirect communication with connections via inputs and outputs. Using an EtherCAT- specific pendant is a more straightforward solution that is easy to integrate with direct plug and play functionality. This ensures a reduction in integration time as well as additional functionality with a reduction in cable size and weight.

ANCA Motion’s pendant uses the industry leading EtherCAT fieldbus which is designed to integrate with any EtherCAT control system. The first handheld remote pendant was designed in 1994 by ANCA Motion for an Integrated Slot Grinder 6-axis Machine using the System 32 CNC control. Today’s design realises the benefits of years of development and proven effectiveness behind it.

Applications requiring mobile operation need an interface that allows the operator to control movement of an axis from the other end of a machine and when not in front of a screen. Therefore, machine tool applications such as grinding or laser machines as well as gantry and a range of automation applications are suited to the more flexible and portable pendant HMI.

Simple and safe operation integrates with smart factories

HMI works best when designed to be an integrated part of the user experience. More than just an add- on accessory, robust performance, practicality, and the right look and feel elevates the HMI concept. Complete customisation options for the ANCA Motion pendant allows Original Equipment Manufacturers (OEMs) and system integrators to have clear and consistent branding for their products. There is flexibility to adjust the faceplates to accommodate the specific requirements of the user. This extends to the buttons, colours and logos. Flexible mounting options, with varying cable lengths supplied as standard, offer flexibility and scalability.

Keeping safety in mind is important in all industries. ANCA Motion’s pendant has increased safety measures built-in to reduce the risk of failures. The dual channel Emergency Stop and the Hold to Run button make operation not only safer for both the machine and the operator but more suited to newer operators with less experience, as there are fewer training requirements for safe operation. With a shortage of expert machinists across many industries, being able to implement technology without intense training is an in-demand feature.

Solving user challenges with innovative design

Typical challenges faced by users of pendant HMIs in the market relate to durability and functionality. An example is the frequent failure of critical components such as the feed switch or speed override. The AMI 5000 is designed to withstand damage with an impact resistant and durable composite body. Being lightweight it is easy to keep portable and is ergonomically designed to fit in the operator’s hand.

Use in harsh operating environments can lead to further failures with cables becoming brittle and oil and dust seeping into emergency contact switches – creating a potential safety hazard. The durable design of the ANCA Motion hand-held pendant means that it can withstand operations in industrial environments while not being heavy or bulky.

Functionality issues typically stem from the use of binary switches in step movements. The problem of not being able to achieve precise and smooth control and movement is solved with ANCA Motion’s Manual Pulse Generator Wheel (MPG). The MPG handwheel allows the user to have precise control via tactile, quality feedback. It is easy and simple to use even for untrained operators.

A history of technology firsts supports a quality product

ANCA Motion is part of the ANCA group (a market-leading manufacturer of motion control systems, CNC grinding machines and sheet metal solutions) with experience in designing and manufacturing flexible control systems, specialising in high precision solutions for CNC and Automation, and creating industry-first technology.

With headquarters in Australia and representation worldwide, including an office in India, ANCA Motion has been involved in motion control for more than 45 years. Its CNC and motion control technology has evolved over this time by proving its performance in demanding applications such as five-axis grinding, high speed laser cutting and factory automation. The highly talented and passionate team at ANCA Motion partners with customers to create bespoke solutions satisfying their unique needs. ANCA Motion offers a range of solutions from turnkey automation control packages to single components such as servo drives, motors, IO modules, HMI and software.