Solutions for Machine, Factory and Process Automation from Leading Japanese Manufacturer

Please brief us about Fuji Electric’s Global Network and Infrastructure?

Founded in 1923, Fuji Electric has pioneered the pursuit of innovation in energy and environmental technology over decades. The brand provides comprehensive responses, from stable energy supply to energy saving and automation solutions, by offering power electronics equipment with world- leading power semiconductors systems, in addition to myriad clean energy-related products.

Fuji Electric has more than 28000 employees and 9 Billion USD business. Over 212 sales, service, and manufacturing bases spread in 99 countries. Our 5 business segment offers over 520K products, and 7 world-class R&D center works tirelessly to innovate the solutions that support sustainable business.

Take us through the Journey of Fuji Electric In India and company current operation?

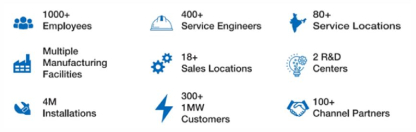

Fuji Electric has been operating in India since 1985. initially, this was through joint ventures to manufacture and sell Instrumentation and UPS products. In 2009, Fuji Electric India Pvt. Ltd., a 100 % Subsidiary of Fuji Electric Group was established. Fuji Electric over the next decade expanded across India to establish leadership in Drives for Lift & Escalator segment and also became a leading Motion control solutions provider for packaging and special purpose machines. In 2019, with the acquisition of Consul Neowatt, the largest Indian UPS company, Fuji Electric India now has a nationwide presence with over 1,000 employees serving customers across all Industry verticals. Fuji Electric India has an aggressive growth plan to become the leading Energy and Automation solutions provider in India by launching new products and solutions supported by expanded sales reach and addition of manpower resources, R&D, and manufacturing capability in India.

What are the market opportunities for your Industrial Automation products in India?

What are the market opportunities for your Industrial Automation products in India?

Industrial automation refers to intelligent machines and programmable logic to automate several industrial processes and minimize human intervention. With the robust development of the Indian manufacturing sector post the Covid slump, there has arisen a need for a more competitive edge in productivity, profitability, safety, and sustainable manufacturing processes. As the Industrial automation improves efficiency and quality of output and maintains consistency throughout the micro and macro-level processes across industries. Our advanced industrial automation solutions are designed to answer the challenges of Drives and Control, Motion Control, Instrumentation, Process Automation and Electrical Distribution & Control. Process automation devices and equipment, which have applications in several sectors, including pharmaceutical, coal, power, oil and gas, cement, and others, are seeing dramatic growth in Indian market today.

How do you plan to position these products?

How do you plan to position these products?

Fuji Electric is all set to essay a critical role as an enabler across the B2B spectrum in India. We are in the process of deploying a comprehensive ecosystem that offers our Japanese technology-powered solutions to a variety of industrial domains. Our production capabilities are being ramped up considerably to meet our expansion goals in the sub-continent. Our core focus areas are Energy and Automation solutions customized to suit the operational feasibility in the Indian market. Most of our core solutions portfolio is being tailored to augment the needs of the contemporary Indian market.

The shift from Traditional Techniques to Digitalized systems coupled with the rise in the Deployment of Automation Across Various Industries, is a perfect fit as we offer customized and innovative solutions in India.

Post-Covid the market is opening a new set of opportunities. According to you, what is the forecast for the automation industry?

As mentioned earlier, the Indian market is growing rapidly due to the economic behemoth in the post COVID global heave. Also the aggressive push from the government involved in infrastructure development and industrial uplift at all levels and encourages organizations to adopt Industrial Automation to optimize resources. In this contemporary scenario, automation solutions are gaining acceptance as industries have started leveraging the power of connected devices to access, analyze and respond to crucial commands. This phenomenon is radically altering the market dynamics. More and more organizations have started embracing this approach to optimize efficiency and reduce operational costs. Still, enterprises across India are yet to gravitate towards Automation to harness the greater benefits. This will remain the focus of most companies in India for the next few years. However, some select players started looking at Industry 5.0 in India for manufacturing a high mix of products efficiently using Robotics and automation.

Can you please brief us about your Manufacturing facilities and R&D activities in India?

Fuji Electric India & motto is “In India for India.” As an organization associated with thought leadership, we have made it our constant endeavor to innovate new solutions that fill the existing vacuum areas in the market. We are fully aware of India’s giant strides in the manufacturing sector via a host of initiatives, incentives, and supporting infrastructure. Fuji Electric has always been known as a forward-thinking organization adopting a proactive approach. We currently have 4 state of the art manufacturing units and 2 R&D centers in which 1 is DSIR approved. We are now heavily invested in formulating an India-specific solutions portfolio that would add further impetus to the rapidly expanding regional manufacturing sector. We are in the process of developing, testing, and deploying several new products and solutions manufactured in India.

Changes does not take place easily. In this sence, could you please share challenges and opportunities in adopting factory automation for manufacturing units?

Enterprises are compelled by the continuous pressure on enhancing processes for profitability improvement, which drives them to continuously look to invest in solutions that will help them increase their productivity with minimal assets. That’s where industrial automation acts as an enabler to increase reliability and efficiency, thereby improving return on investment (ROI). Industrial automation enhances production rate and quality by incorporating innovative and integrated technologies, thereby reducing costs associated with the production process.

As mentioned previously, the market for automation in India has been growing significantly over the last decade due to the increasing need for reliable and cost-effective ways of production. According to a research report, The Indian industrial automation industry is expected to reach 2.5 billion by 2023 with growth driven by the rapid adoption of modern technology backed by cost-saving features. The demand for factory automation solutions in India is anticipated to surge with an increase in domestic manufacturing and an emphasis on increased process efficiency.

However, longer adoption time, large investment, Skilled manpower are some of the challenges enterprises face when adopting factory automation.