Electromobility calls for new ideas

At BENTELER, clever minds are working on solutions that customers might urgently need in the future. Together with specialized development partners such as TRUMPF, they are working on new laser welding processes that can be used to efficiently manufacture battery housings for electric vehicles.

They are quiet, they are sustainable, they are the future: electric vehicles have really taken off in recent months: In the first half of 2021, 2.65 million new all-electric vehicles were registered worldwide. At their heart are high-voltage battery storage units and the battery boxes that surround them. The latter protect the sensitive cells not only from the consequences of crashes, but also from influences such as moisture and temperature fluctuations that can have a negative impact on battery performance. So far, these battery boxes have mainly been made of aluminum alloys. They are lightweight and thus aim to maximize the range of the vehicles. The developers at the metal process specialist BENTELER Automotive, headquartered in Paderborn, have long been aware that this is only one side of the coin. For them, steel and in particular stainless steel offers some advantages that cannot be dismissed despite its somewhat higher weight, as Christian Buse, Team Leader Research & Development of the Automotive Division at BENTELER tells us: “For our customers, the cost factor is increasingly important. It is increasingly outstripping lightweight construction. But stainless steel scores not only with lower material costs. It is corrosion-resistant and has a high melting point. In the event of a vehicle fire, this can be crucial for the safety of the occupants.” In addition, the material is – at least as things stand today – more sustainable in production than aluminum, depending on the supplier, due to its high recycling content. “But what is quite decisive is that stainless steel can basically be welded excellently with a laser. What we need for e-mobility is a reproducible process and a method that meets the high

requirements for the seal welding of battery boxes.” BENTELER already had positive experience with laser welding and systems from TRUMPF when joining exhaust gas systems for combustion engines. So Buse and his colleague Conrad Frischkorn turned to their long-standing partner with their idea for battery boxes 2020.

Know-how across the entire process

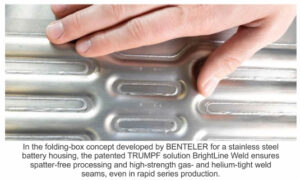

“Our development goal was a concept for a flexible and scalable battery box made of stainless steel with a cooling plate integrated into the bottom. The folding-box concept we developed serves to ensure crash safety, makes optimum use of the battery’s installation space and gets by with fewer and shorter joints,” explains Frischkorn. Automated production requires a punch laser system, a bending cell and a laser welding system. For all of these technologies, TRUMPF has the appropriate equipment and the know-how to precisely coordinate all of the machining processes. In addition, Buse and Frischkorn found a partner at their level in Mauritz Moeller from TRUMPF’s Automotive Industry Management. Technology and application

experts specializing in a particular field work in different industry management areas at TRUMPF. Together with customers, they develop new, trend-setting products for the industry. Moeller’s focus is on the battery pack, i.e. the drive battery of electric vehicles and its components. The task defined by BENTELER was multi-part, according to Moeller: “What they wanted was support in the production engineering design of a battery box with an integrated cooling plate. The TRUMPF experts were to coordinate the necessary manufacturing technologies and set up a fully automated process chain for series production. A fast and reproducible laser welding process for gas- and helium-tight welding of the battery box was also on the list of requirements.” Moeller and his team set to work and presented a solution after only a short time. With the established, patented TRUMPF technology BrightLine Weld, it is possible to weld stainless steel without spattering, even at the high speeds of series production. This eliminates the need to rework the component and protects the machine and the focusing optics. For BENTELER’s task, however, it was most important that the technology can be used to produce perfect gas- and helium-tight seams, as explained by Moeller: “The high welding speed requires tailored input of thermal energy into the material. This is the only way to ensure a stable molten pool while welding. There is no material spraying away during the machining when the weld is being formed. Pores can form, and that’s exactly what BrightLine Weld prevents.”

“Impossible” not accepted here

Spurred on by this success, Buse and Frischkorn immediately set their sights on the next challenge. Christian Buse explained: “There is still a lot of scope for design available when it comes to e-mobility. In our day-to-day work, we use this to look at solutions that the market doesn’t need today, maybe not even tomorrow, but eventually.” The idea of manufacturing the battery housing from stainless steel has yet to catch on with customers. So Buse and Frischkorn are now thinking about how the positive results achieved in gas-tight welding of stainless steel can also be applied to aluminum, which is still popular at present. “Aluminum does have a high level of acceptance among our customers,” said Frischkorn. “But most of them advised us against trying to seal weld this material using lasers.” But the two developers are not discouraged by this, as Buse reported, “Our motto is: ‘We make it happen’ and we see it as our task to constantly develop existing processes and put products to the test again and again. This gives us a head start. If you only start thinking and developing something new when the market asks for it, you’re too late.”

» There are hardly any standards in e-mobility. Everything is literally on the move. And we want to be prepared for everything.

Be ready for what’s coming

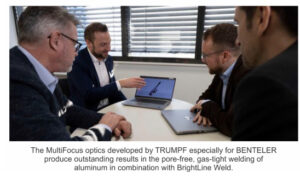

The TRUMPF technology and application experts working with Mauritz Moeller also have this attitude. They set to work developing a completely new technology especially for BENTELER: the so-called MultiFocus optics. The combination of a TruDisk laser with BrightLine Weld plus patented MultiFocus optics achieves what has not been possible before: gas-tight welding of aluminum. BrightLine Weld first splits the laser beam between the ring and the core. The processing optics also split it into four individual spots, in each of which the ring and core are superimposed. The spots are positioned relative to each other to create a continuously open keyhole. This prevents gas inclusions and thus collapsing of the weld seam. Until now, this has been the sticking point when welding aluminum.

Initial tests and CT images show that the process can be used to produce high-strength and virtually pore-free welds. Buse and Frischkorn are now working on validating the results when used in larger series. Buse: “We also see this development more in the context of demonstrating what is possible. There are hardly any standards in e-mobility. Everything is literally on the move. And we want to be prepared for everything.”

In addition to its own attitude of not buckling and burying its head in the sand even in the face of headwinds, BENTELER is building on development partners with the same mindset, as it has in the past. This has many advantages, said Frischkorn: “When specialized partners throw their know-how together for a common development goal, the work is more efficient, the development time is shorter, and the costs are lower.” Ultimately, everyone involved benefits from the collaboration, added Buse: “There is so much that is still possible in e-mobility. It’s important to stay open in all directions, and we appreciate that about TRUMPF as well.”